Lihlahisoa

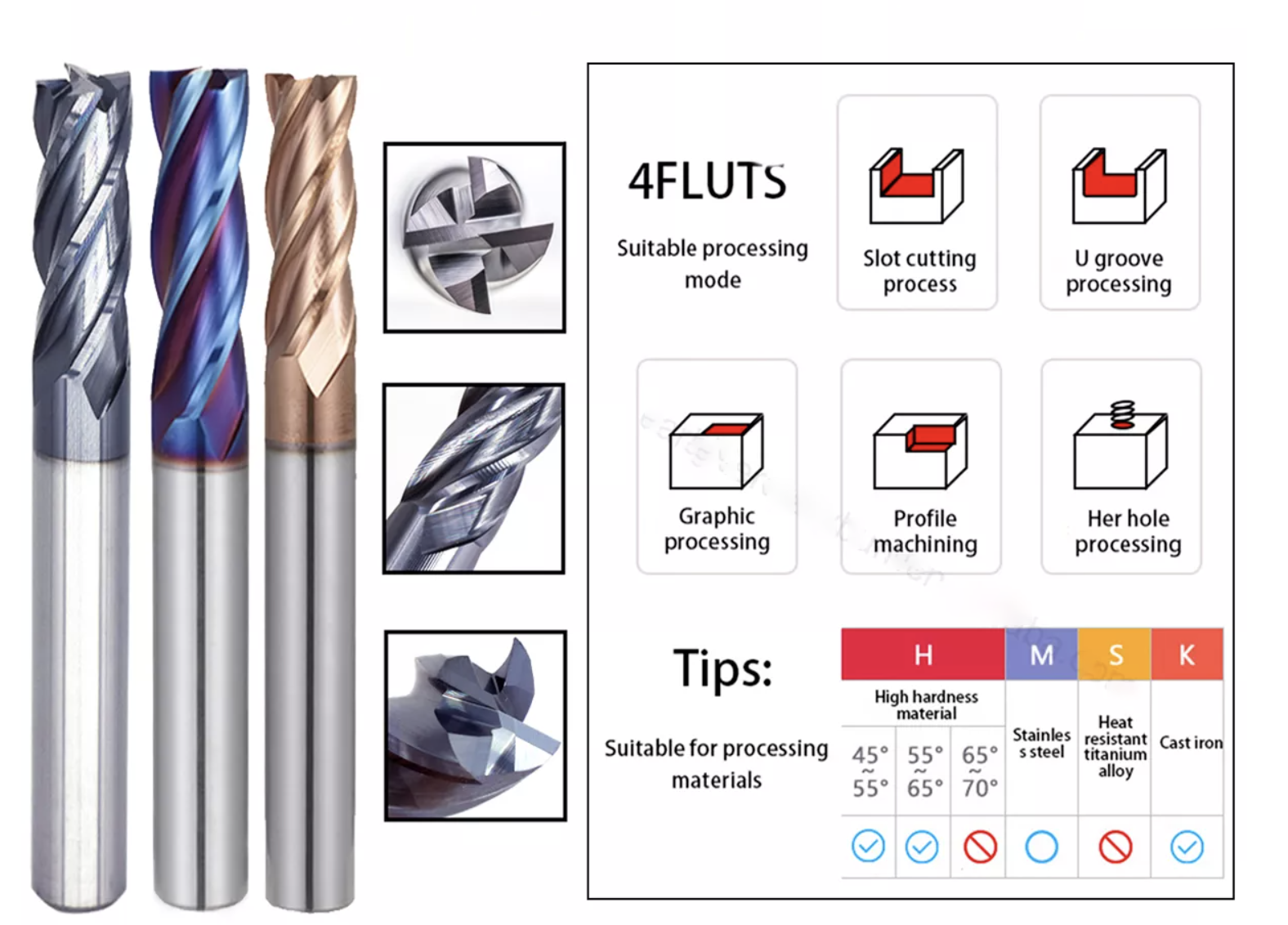

Solid Carbide Fresa Diamond Coating CNC 4 Flutes Square End Mill Cutters

Specificatoin e qaqileng

Li-cutter tsena tsa Kedel square end tse 'ne tsa bolelele ba lekolilo la carbide end milling li na le angle ea 30 ea helix' me li seha bohareng bakeng sa ho plunging, slotting le profiling. Joalo ka lisebelisoa tsohle tsa rona tse tiileng tsa carbide, limiloana tsena tsa stub end li etsoa ho sebelisoa mechini ea morao-rao, lits'ebetso tsa tlhahiso le mekhoa ea tlhahlobo, e ba etsa khetho e ratoang ea li-endmill tsa carbide bakeng sa machinist a batlang ho hlahisa likarolo tsa boleng bo holimo tse nang le lisebelisoa tse ngata tsa bophelo. Keketso ea rona ea ho roala ALTiN e re lumella ho eketsa lebelo le ho fepa hammoho le bophelo bo bolelele ba lisebelisoa.

1. E thusa ka botlalo ho matha maemong a macha a macha, ho fella ka boleng ba bokaholimo.

2. Ts'ebetso e babatsehang ea ho sebetsa ka machining titanium, tšepe e sa hloekang le li-alloys tse phahameng tsa mocheso.

3. Ho roala ho fana ka nako e telele ea lisebelisoa-bophelo kapa ho eketseha ha litekanyetso tsa ho itšeha.

4. E loketse mefuta eohle ea tšepe kapa tšepe.

Premium Sub-Micrograin Solid Carbide End Mill

4 Folutu

Square End

Qetello e le 'Ngoe

30 ° Helix

Stub Length End Mills

Center Cutting Carbide Endmill

ALTiN e Apesitsoe Bakeng sa Keketseho ea Ts'ebetso & Bophelo ba Sesebelisoa

E entsoe chaena

ALTIN Coating: Sekoaelo se phahameng sa ts'ebetso bakeng sa ho sila litšepe tse sa jeleng paate, litšepe tsa k'habone, litšepe tsa alloy, le tšepe ea tšepe. Sehlahisoa sena se mamella mocheso haholo 'me se ka sebelisoa ka se pholileng kapa ntle le sona. E ikhethile ka har'a lisebelisoa tse thata tsa mochini moo sekhomaretsi se leng holimo haholo.

Kopo

1. Bakeng sa Copper, Cast Iron, Carbon steel, Tool steel, Mold steel, Die steel, Stainless steel, Plastic, Arcylic, joalo-joalo.

2. Bakeng sa sefofane, lipalangoang, lisebelisoa tsa bongaka, tlhahiso ea sesole, nts'etsopele ea hlobo, lisebelisoa le lisebelisoa, joalo-joalo.

Mabapi le Coating

| Selelekela sa Coating | ||||||

| ENDMILL MPHATO | Lebitso la ho roala | Mmala | Hv | μm | Khohlano | The Max ℃ |

| Ho roala ha HRC45 | AlTiN | ntsho | 3300 | 1--4 | 0.7 | 850 ℃ |

| Ho roala ha HRC55 | TiSiAlN | e borone | 3400 | 1--4 | 0.7 | 900 ℃ |

| Ho roala ha HRC60 | AlCrSiN | ntsho | 4000 | 1--7 | 0.35 | 1100 ℃ |

| Ho roala ha HRC65 | naCo 3 Blue | putsoa | 4500 | 1--7 | 0.45 | 1200 ℃ |

| Ho roala ka tšepe e sa hloekang | naCo 3 Khauta | khauta | 4500 | 1--7 | 0.55 | 1200 ℃ |

Mabapi le Ho Seha

Lintlha tsa Sehlahisoa