Lihlahisoa

1/4" (6mm) Shank Tungsten carbide rotary burrs

Tlhaloso ea Tlhahiso

Faele e entsoeng ka samente ea carbide rotary, eo hape e tsejoang ka hore ke seha sekontiri se siiloeng sa carbide se lebelo le holimo, sekontiri se entsoeng ka samente sa carbide, joalo-joalo, se sebelisoa hammoho le leloala la motlakase le lebelo le phahameng kapa lisebelisoa tsa moea. Faele e entsoeng ka samente ea carbide rotary e sebelisoa haholo mecheng, likoloing, likepeng, indastering ea lik'hemik'hale, ho betla mesebetsi ea matsoho le makaleng a mang a indasteri. Hard alloy rotary file e ka sebelisoa ho sebetsana le tšepe e entsoeng ka tšepe, tšepe ea carbon, tšepe ea alloy, tšepe e sa hloekang, tšepe e thata, koporo le aluminium, joalo-joalo.

Advatages

1. E ka sebetsana le tšepe e entsoeng ka tšepe, tšepe e entsoeng ka tšepe, tšepe ea carbon, tšepe ea alloy, tšepe e sa hloekang, koporo, aluminium le lisebelisoa tse ling, le marble, jade, lesapo le tse ling tse seng tsa tšepe. Boima ba ho sebetsa bo ka fihla HRA ≥85.

2. Ha e le hantle e ka nkela lebili le lenyenyane sebaka ka mofeng, 'me ha e na tšilafalo ea lerōle.

3. Ts'ebetso e phahameng ea tlhahiso. Ts'ebetso e sebetsang e phahame ka makhetlo a mangata ho feta ea faele ea matsoho 'me e batla e phahame ka makhetlo a leshome ho feta ea lebili le lenyenyane le silang le nang le molamu.

4. Boleng bo botle ba ho sebetsa le ho qetela ho phahameng. E khona ho sebetsana le likheo tse fapaneng tsa hlobo tse nepahetseng haholo.

5. Bophelo bo bolelele ba tšebeletso. E tšoarella ka makhetlo a 10 ho feta ea seha sehalo sa tšepe se lebelo le holimo ka makhetlo a 200 ho feta a lebili le lenyenyane le silang.

6. Ho bonolo ho e tseba, ho bonolo ho e sebelisa, e bolokehile ebile e ka tšeptjoa.

7. Litšenyehelo tse felletseng tsa ts'ebetso li ka fokotsoa makhetlo a mangata.

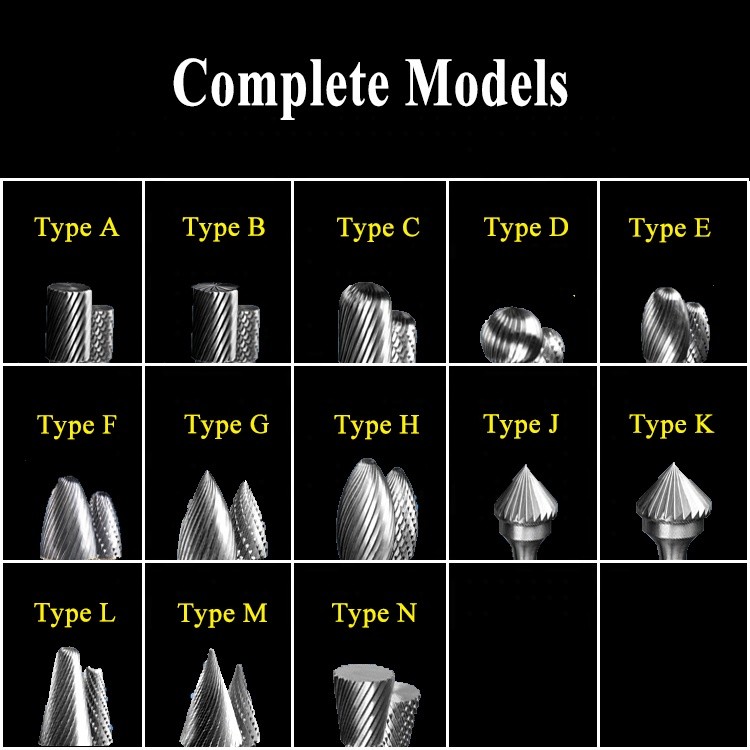

Mefuta e ka Sehloohong

Shape A Cylindrical Plan End

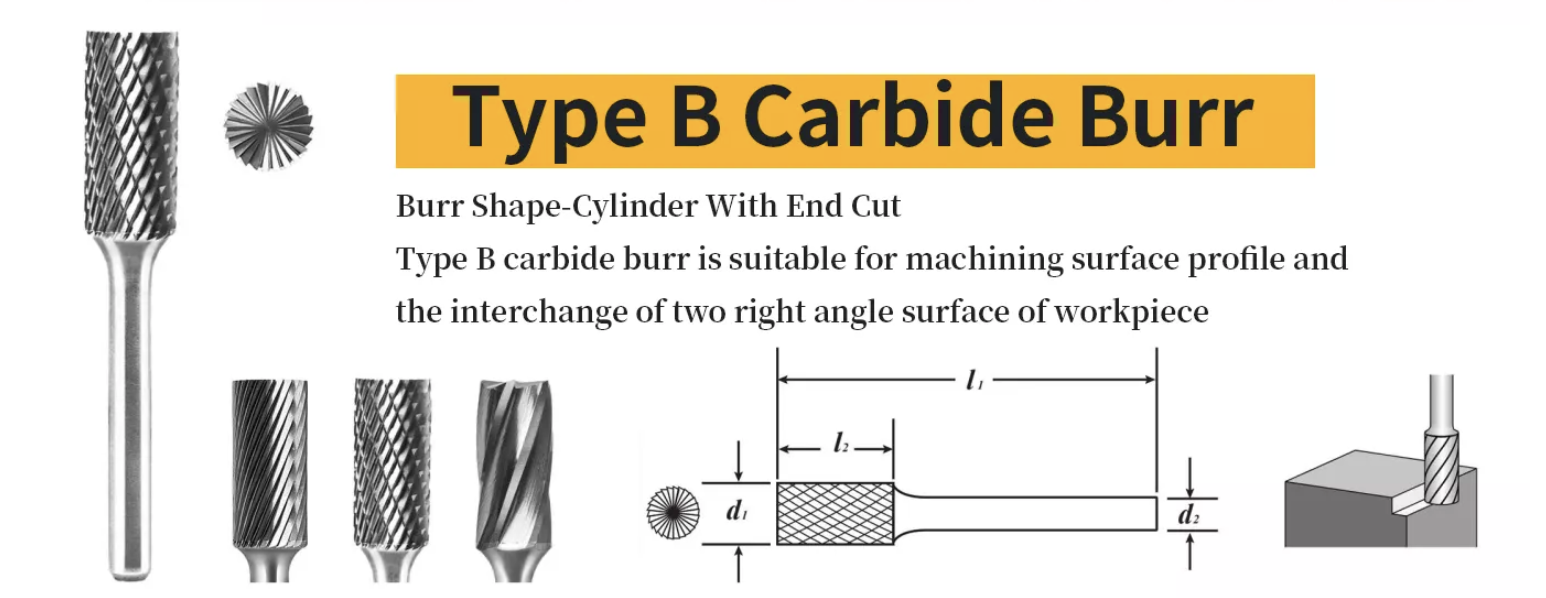

Sebopeho sa B Cylindrical End Cut

Sebopeho sa C Cylindrical Ball Nose

Shape D Ball Shape

Sebopeho sa Oval Shape

Sebopeho sa F Sefate Radius Qetellong

Sebopeho sa G Point Sefate Sebopeho

Sebopeho sa H Flame Shape

Sebōpeho sa J 60-degree countersink

Sebopeho sa k'hamera ea K 90-degree

Shape L Cone Radius End

Shape M Cone Sebopeho se Supileng

Shape N Inverted Cone

Boholo ba Boholo

| Metric Size | ||||||

| Shank Diameter(mm) | Cutter Diameter(d1) | Length of Cut(l2) | Shank Diameter(d2) | Kakaretso Bolelele(L1) | Tool No. | Mofuta |

| 6.0 | 6 | 16 | 6 | 50 | B60616 | tiileng |

| 6 | 16 | 6 | 61 | B60616 | brazed | |

| 8 | 20 | 6 | 65 | B60820 | brazed | |

| 10 | 20 | 6 | 65 | B61020 | brazed | |

| 11 | 20 | 6 | 70 | B61125 | brazed | |

| 12 | 25 | 6 | 70 | B61225 | brazed | |

| 16 | 25 | 6 | 70 | B61625 | brazed | |

| 20 | 25 | 6 | 70 | B62025 | brazed | |

| 25 | 25 | 6 | 70 | B62525 | brazed | |