Lethathamo la Ts'ebetso ea Material

Tšebeletso ea Customization

Re ka amohela lits'ebeletso tse ikhethileng. Re ka etsa OEM ho latela litšoantšo tsa hau le ODM ho latela litlhoko tsa hau tsa ts'ebeliso.

Nako e potlakileng ea ho fana ka lihlahisoa tse hlophisitsoeng ke matsatsi a supileng.

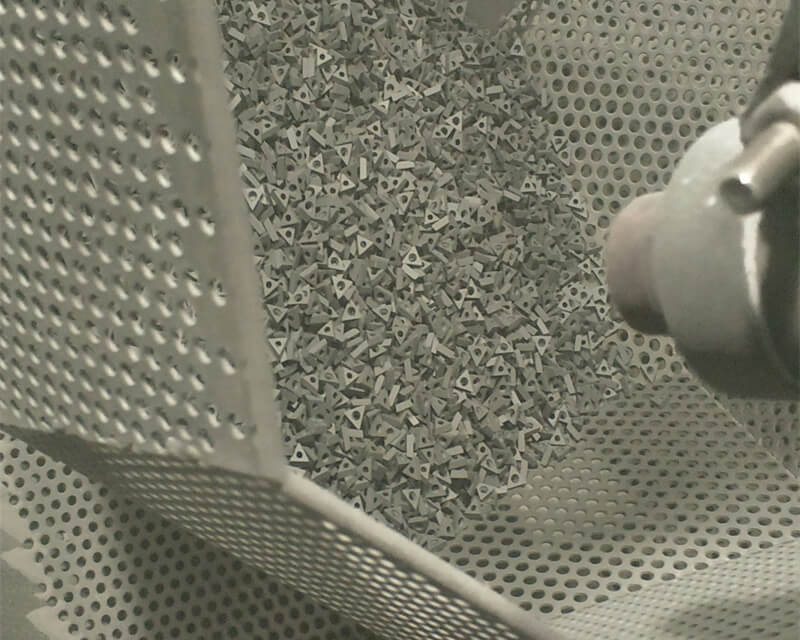

Mokhoa oa Tlhahiso

3.Spray ho omisa tora

4.Tobetsa ho bopa

5.Low khatello ea sintering sebōpi sintering

6.Ho phekola ka holim'a metsi-Sandblasting

7.Tlhahlobo

8.Qetella ho sila

9.Hloekisa le ho paka

10.Ho hlahloba hape feme

LEANO LA THEPA E KHUTLISOANG

Bakeng sa mathata a boleng ba sehlahisoa a netefalitsoeng ke k'hamphani ea rona, re tla fana ka lihlahisoa tse ncha ka nako e nepahetseng, 'me litšenyehelo tsa lipalangoang li tla lefelloa ke k'hamphani ea rona. 'Me u khutlisetse lihlahisoa tse sa tšoaneleheng ka nako

Tshebeletso ya Logistics

Re sebelisana 'moho le lik'hamphani tse' nè tse kholo tsa machaba, DHL, FedEx, UPS le TNT. Ka kakaretso, moeli oa nako ea lipalangoang o pakeng tsa matsatsi a 7-10.

Hape re amohela litsela, ail, lifofane le lipalangoang tsa leoatle.

Netefaletso ea boleng

Nako ea tiiso ea boleng ba lihlahisoa tsa rona hangata ke selemo se le seng. Haeba ho na le mathata a boleng ka nako ea tiisetso, re ka khutlela le ho e nkela sebaka, empa re ke ke ra jara bothata ba tšenyo ea sehlahisoa e bakoang ke tšebeliso e fosahetseng.

Taolo ea Boleng

Theko ea thepa e tala--- Tlhahiso e se nang letho---Sehlahisoa se qeta Maching--- Coating processing

1. Ke hore, WC, Co, Ta, Nb, Ti le lisebelisoa tse ling tsa tlhahiso ea carbide tse entsoeng ka samente li rekoa fekthering bakeng sa tlhahlobo ea boleng.

2. Ho kopanya, ho sila bolo, granulation, ho hatella, ho sintering, teko ea thepa ea 'mele e se nang letho,' me u kenye mokhoa o latelang ka mor'a ho feta tlhahlobo.

3. Sekoti se feta ka mekhoa ea ts'ebetso e kang selikalikoe se ka ntle, sekoti se ka hare, sefahleho sa ho qetela, khoele, ho etsa phekolo ea ho sila le ea bohale, 'me e kena ts'ebetsong e latelang ka mor'a ho feta tlhahlobo.

4. Ho roala likhoebo tsa tšebelisano-'moho leano li kenyelletsa Balchas, aenbond, Suzhou Dingli, joalo-joalo, ho tla bolokoa ka mor'a ho feta tlhahlobo.