Cemented carbide ke mofuta oa thepa e thata e entsoeng ka tšepe e thata ea refractory le tšepe e kopanyang, e hlahisoang ke metallurgy ea phofo 'me e na le khanyetso e phahameng ea ho apara le ho tiea ho itseng.Ka lebaka la ts'ebetso ea eona e ntle haholo, carbide e entsoeng ka samente e sebelisoa haholo ho seha, likarolo tse sa sebetseng, meepo, ho cheka ha jeoloji, merafo ea oli, likarolo tsa mochini le masimo a mang.

Ts'ebetso ea tlhahiso ea carbide e entsoeng ka samente e kenyelletsa lits'ebetso tse tharo tse kholo: ho lokisa motsoako, ho bopa ha mochini oa khatiso le sintering.Joale ts'ebetso ke efe?

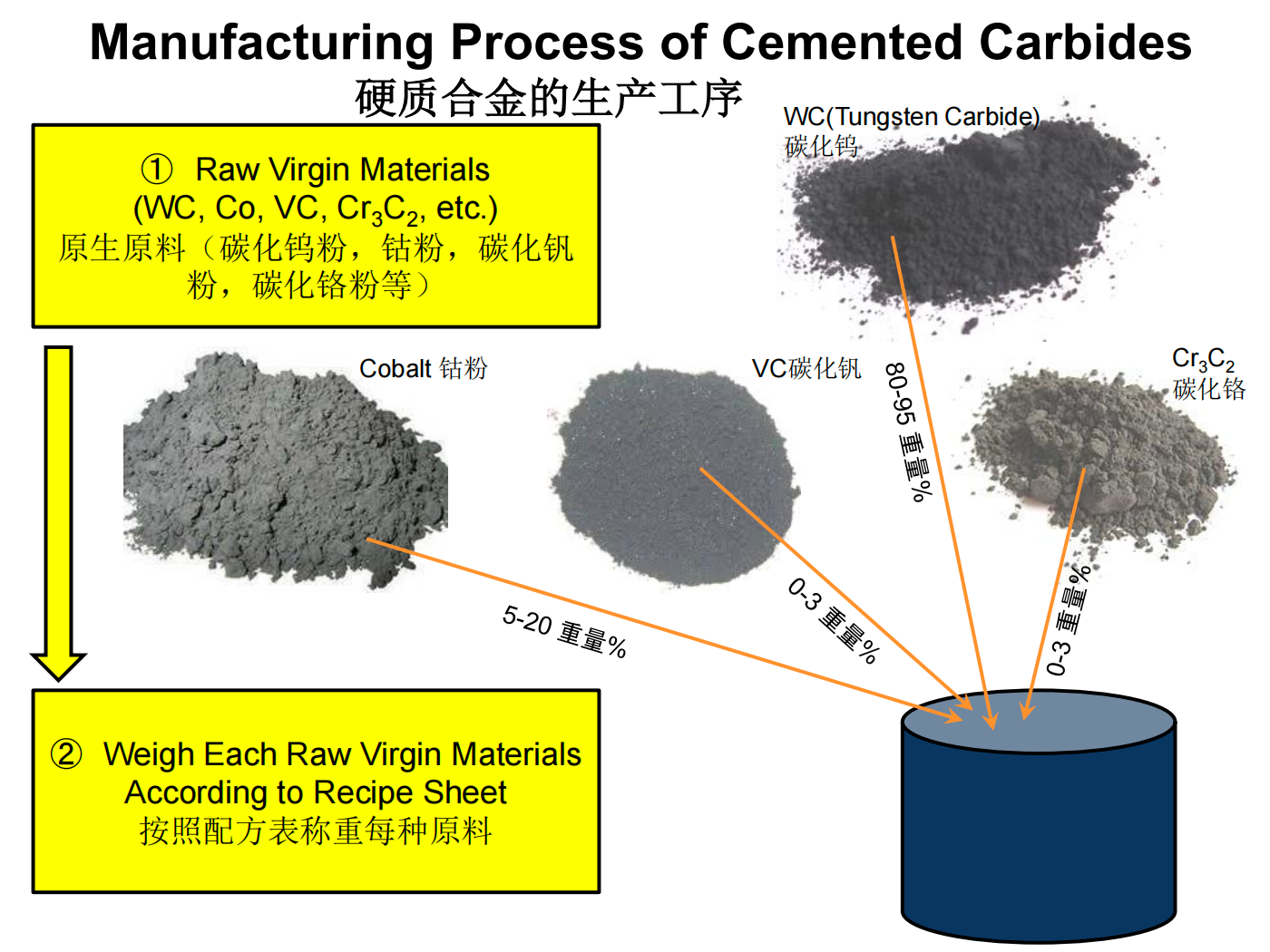

Batching tshebetso le molao-motheo

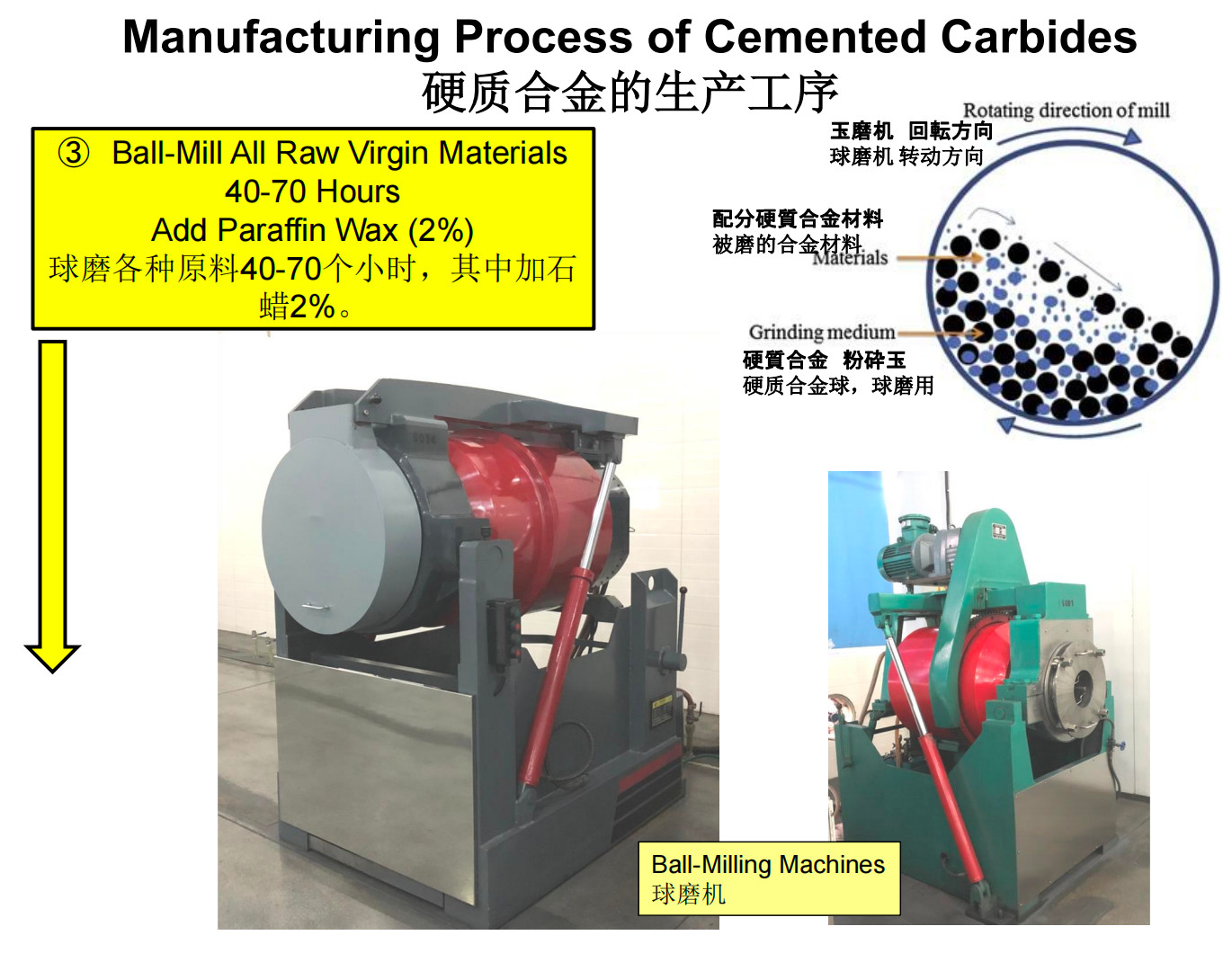

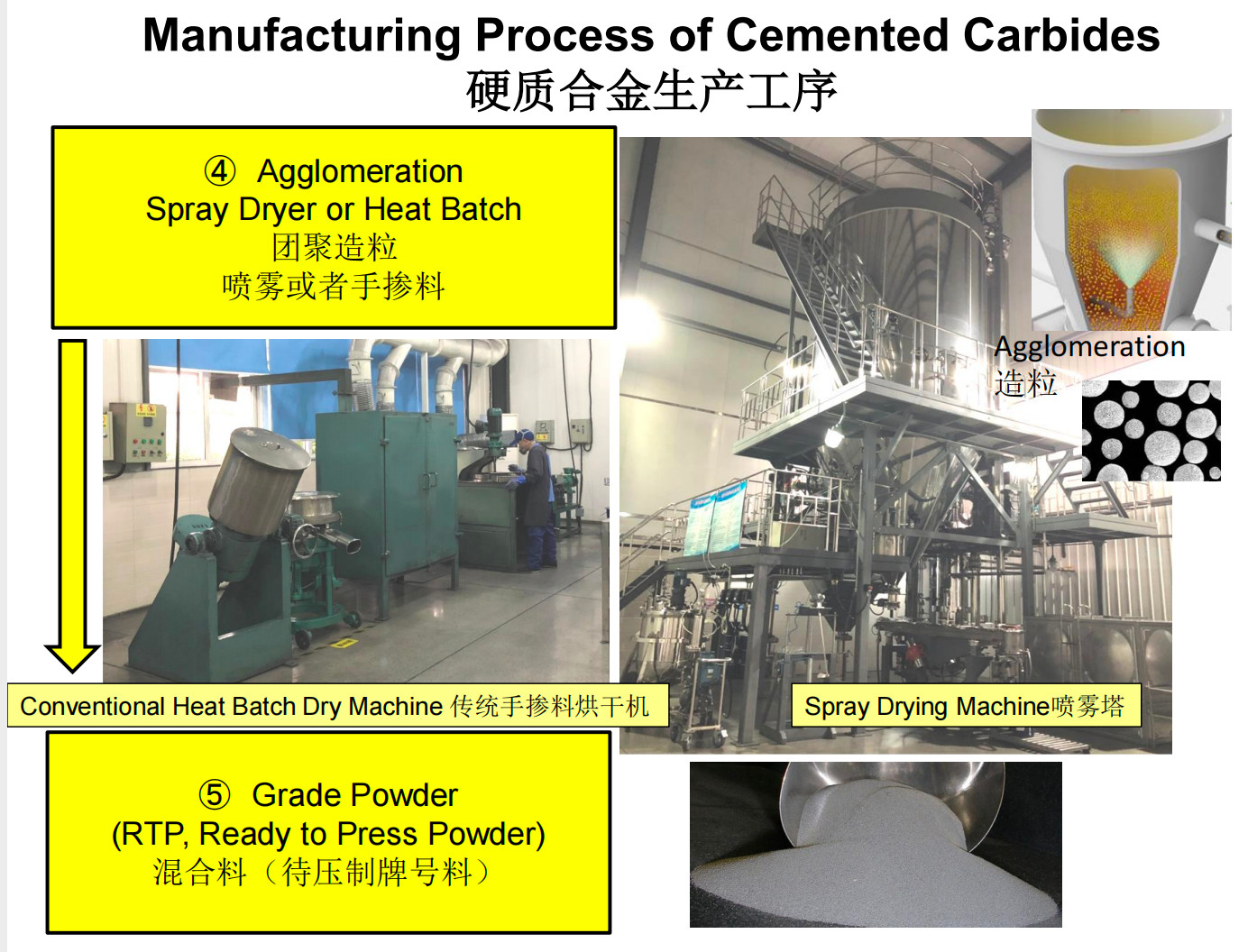

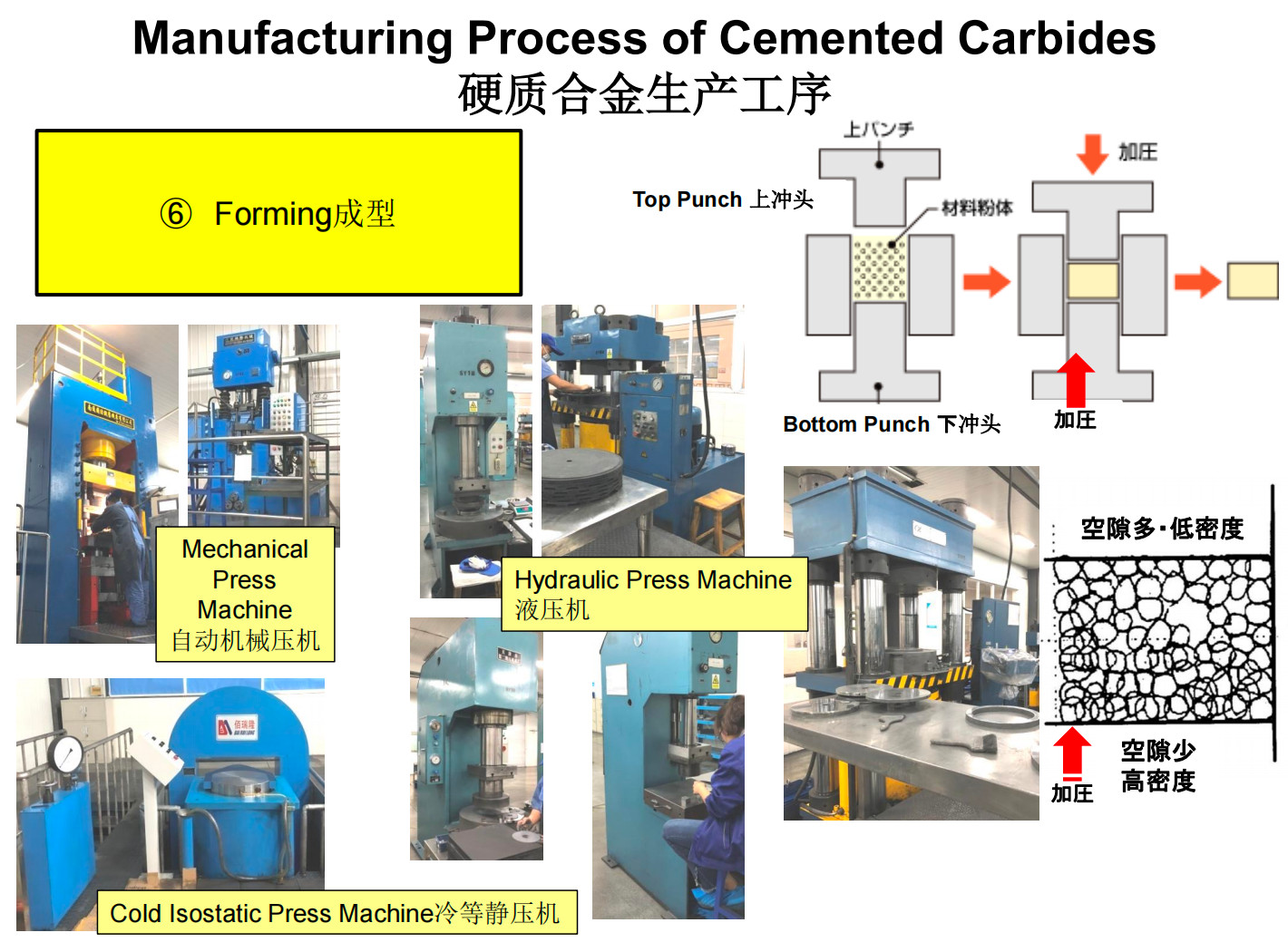

Beha boima ba lisebelisoa tse tala (tungsten carbide powder, cobalt powder, vanadium carbide powder, chromium carbide powder le li-additives tse nyane), li kopanye ho latela tafole ea foromo, u li kenye ka leloaleng la bolo kapa motsoako ho sila lisebelisoa tse fapaneng tse tala. bakeng sa lihora tse 40-70, eketsa boka ba 2%, hloekisa le ho aba ka mokhoa o lekanang lisebelisoa tse tala ka leloaleng la bolo, ebe o etsa motsoako ka litlhoko tse itseng tsa sebopeho le boholo ba likaroloana ka ho omisa kapa ho kopanya letsoho le ho thothomela, Ho finyella litlhoko tsa ho hatella le ho qoela.Kamora ho penya le ho qoelisoa, likheo tsa carbide tse samente lia ntšoa ebe lia phutheloa ka mor'a tlhahlobo ea boleng.

Lisebelisoa tse tsoakiloeng

Ho sila ka metsi

Ho kenella ka sekhomaretsi, ho omisa le granulation

Tobetsa ho bopa

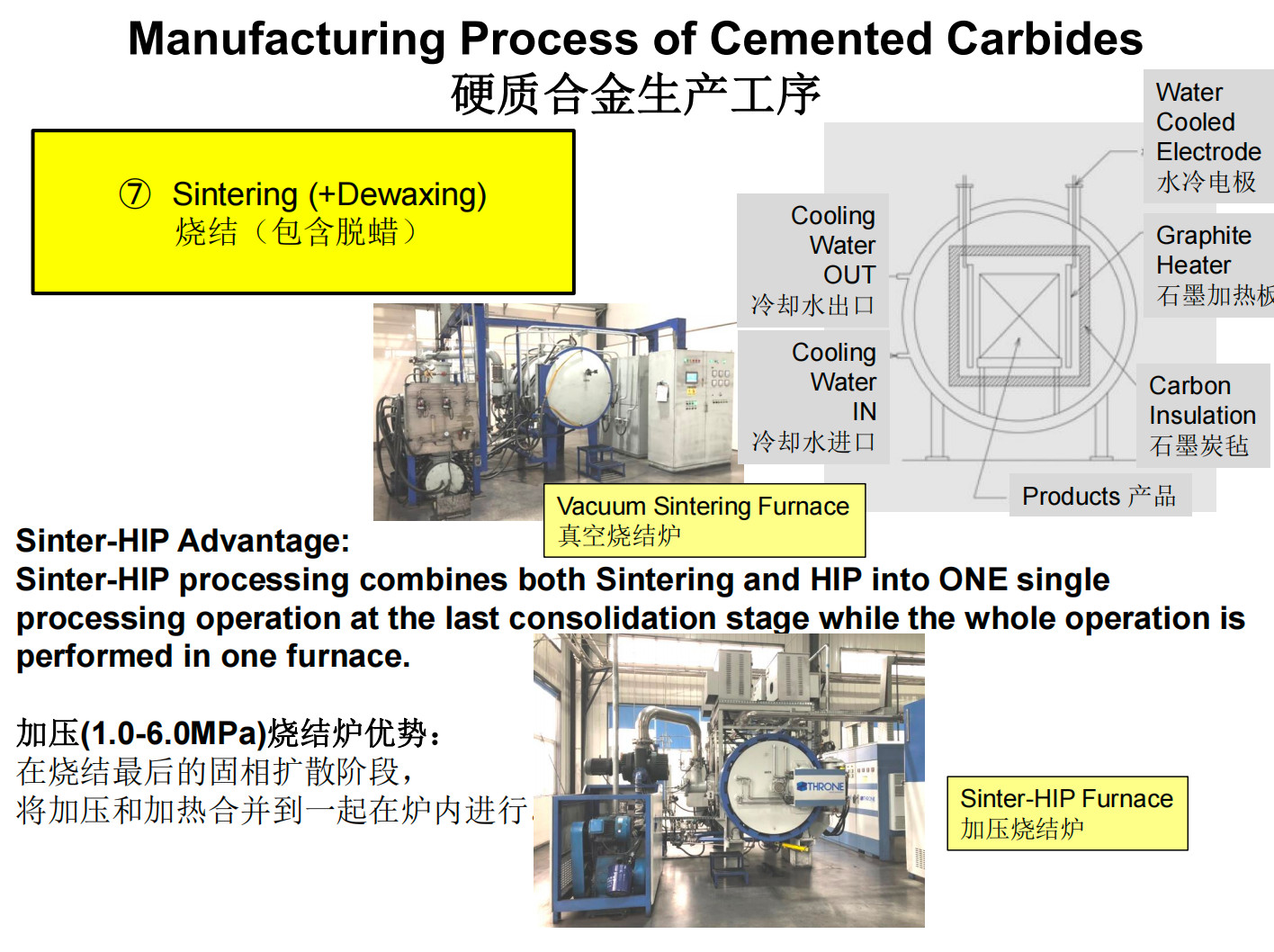

Sinter

Carbide e entsoeng ka samente e se nang letho

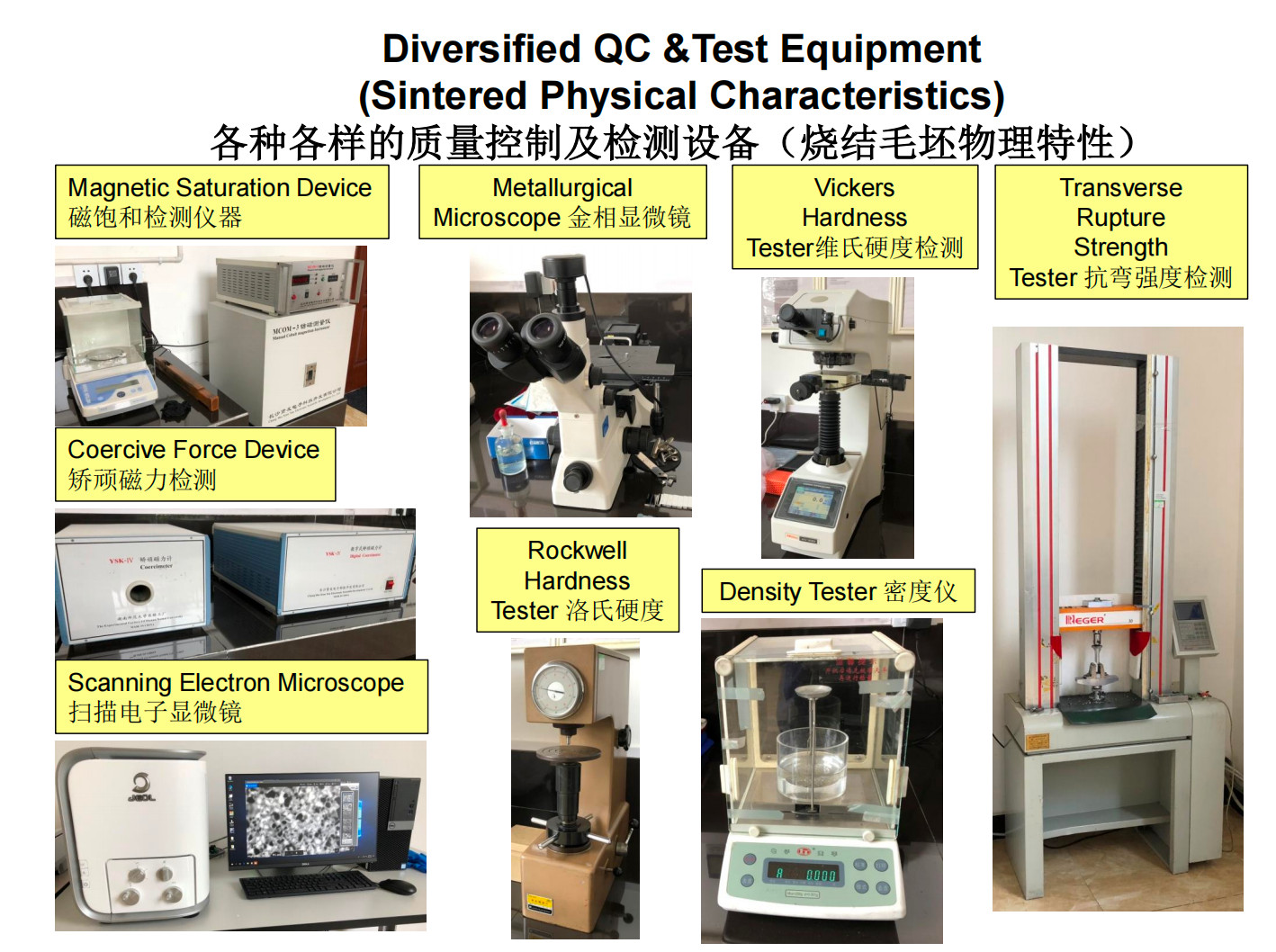

Tlhahlobo

Vacuum ke eng?

Vacuum e kang ena ke sebaka se nang le khatello ea khase e nyane haholo ho feta khatello ea sepakapaka.Hangata litsebi tsa fisiks li bua ka liphetho tse nepahetseng tsa tlhahlobo ea boemo ba vacuum e felletseng, eo ka linako tse ling e e bitsang vacuum kapa sebaka sa mahala.Joale sekheo se sa fellang se sebelisoa ho emela sekheo se sa fellang ka laboratoring kapa sepakapakeng.Ka lehlakoreng le leng, lits'ebetsong tsa boenjiniere le tsa 'mele, re bolela sebaka leha e le sefe se tlase ho feta khatello ea sepakapaka.

Litšitiso / likotsi tse tloaelehileng tlhahisong ea lihlahisoa tsa carbide tse samenteng

Ho khutlela morao ho lisosa, liphoso / likotsi tse atileng haholo tsa tlhahiso ea carbide li ka aroloa ka mekhahlelo e mene:

Bofokoli ba likarolo (mokhahlelo oa ETA oa hlaha, lihlopha tse kholo tsa likaroloana li theha, ho phatloha ha phofo)

Mathata a ho sebetsa (mapetso a tjheseletsa, mapetsong a terata, mapetsong a mocheso)

Likotsi tsa tikoloho (khoholeho, bofokoli ba khoholeho, joalo-joalo)

Likotsi tsa mochini (joalo ka ho thulana ha brittle, ho felloa ke matla, tšenyo ea mokhathala, joalo-joalo)

Nako ea poso: Jul-27-2022