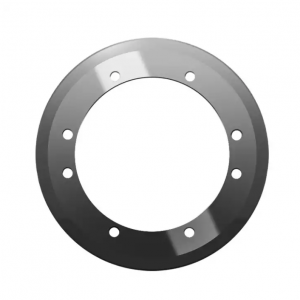

Lihlahisoa

Wheel ea ho sila bakeng sa lehare la carbide sliter

Tlhaloso ea Sehlahisoa

Abrasive: Diamond/CBN

Bond: Resin

Lisebelisoa tsa Substrate: Aluminium

Boholo ba lijo-thollo: Granularity e khethehileng bakeng sa indasteri ena

Boholo ba lebili le silang la daemane: Feme ea rona e ka sebetsana le lebili la ho sila ka boholo leha e le bofe pakeng tsa D10-D900mm, le ho iketsetsa tlhahiso ho latela litlhoko tsa bareki.

Sebopeho sa lebili le silang la daemane: sephara, senoelo, sekotlolo, sejana, bevel e le 'ngoe, bevel habeli, concave habeli, joalo-joalo E ka boela ea etsoa ho latela litšoantšo tsa bareki.

Kamora lilemo tse ngata tsa boiphihlelo ba tlhahiso, re se re tloaelane haholo le mabili a silang a neng a sebelisoa indastering ea masenke.

(Mehala e Tloaelehileng ea Lihlahisoa indastering ea Corrugated: Fosber, Agnati, BHS, Peters, Isowa, Marquip, Mitsubishi, TCY, HSIEH HSU, JASTU, K&H, KAI TUO, MHI,MINGWEI.)

* Lebitso la Sehlahisoa: Mabili a sila bakeng sa melapo ea BHS Hlahisa.

* Boemo ba Wheel e silang: D50*T10*H16*W4*X2 e nang le bearing. (D-Diameter; Botenya ba T; H-Hole; W-Bophara ba Lera e hlabang; Botenya ba X ba Lera la Abrasive).

* Ts'ebeliso ea Wheel e silang: Li-blade tse sebelisetsoang ho seha karete ea masenke kapa lebokose la mabokose, boto ea pampiri.

* Lebili le Leng la ho Sila: Ho taka ho amohelehile

* Taolo ea boleng: e tebile ebile e nepahetse haholo

Mabili a sila a litaemane a ka har'a mefuta e latelang

1. Diamond resin bonded sila lebili e sintered le resin tlanngoeng;

2. Lebili la ho sila le entsoeng ka tšepe ea daemane, le tsejoang hape e le lebili la ho sila la taemane la boronse, le kenngoe ka tšepe bond;

3. Diamond ceramic bond grinding lebili e entsoe ka sintering kapa sticking ceramic bond;

4. Electroplated diamond grinding wheel, lera abrasive e koahetsoeng ka substrate ka electroplating.

Litšobotsi tsa Wheel e silang ea Diamond

1. Abrasive ea daemane e batla e le bohale, kahoo bokhoni ba ho sila ba lebili la ho sila la taemane bo batla bo phahame. Karo-karolelano ea lebili le silang la daemane ho lebili le tloaelehileng la ho sila ke hoo e ka bang 1: 1000, 'me ho hanyetsa ho roala le hona ho phahame haholo.

2. Lebili la ho sila la daemane le na le thepa e ntle ea ho itšeha, mocheso o fokolang oa mocheso nakong ea ho sila, 'me ha ho bonolo ho thibela, ho fokotsa ts'ebetso ea ho chesa ha mosebetsi nakong ea ho sila.

3. Likaroloana tsa abrasive tsa daemane li ts'oana ebile li ntle haholo, kahoo lebili la ho sila la daemane le na le ts'ebetso e phahameng ea machining, 'me e sebelisoa haholo-holo bakeng sa ho sila ka mokhoa o nepahetseng, ho sila ka mokhoa o nepahetseng, ho sila ka thipa, ho polishing le mekhoa e meng.

4. Lebili la ho sila la daemane le ka batla le se na lerōle, le finyella litlhoko tsa indasteri ea kajeno bakeng sa tšireletso ea tikoloho.

Lintlha tsa Sehlahisoa

Kopo