Lihlahisoa

Lihlahla tsa Sleeves tsa Tungsten Carbide tse Kentsoeng Bakeng sa Tšimo ea Oli ea Submersibe

Kenyelletso ea Sehlahisoa

Lisebelisoa tsa sleeve tsa Tungsten carbide li pharaletseng, e leng sesebelisoa sa ho sireletsa sehlopha sa likarolo.Ke mosebetsing oa sebele 'me karolo le morero oa tikoloho ea eona ea kopo li na le kamano e kholo.

Lisebelisoa tsa li-valve, lihlahla li kenngoe ka har'a sefi sa valve stem cap, e le ho fokotsa ho lutla ha valve, ho tiisa;ho jara lits'ebetso, ts'ebeliso ea sehlahla ho fokotsa ho roala pakeng tsa ho beha le setulo sa shaft, qoba lekhalo lipakeng tsa shaft le ho eketseha ha lesoba joalo-joalo.

Tlhahiso ea sleeve ea tungsten carbide le ts'ebetso ea matla a phahameng, e ka mamella mojaro oa nako e telele, ka botsitso bo phahameng ba lik'hemik'hale, alkali, joala, ether, hydrocarbons, acid, oli, detergent, metsi (metsi a leoatle), 'me ha e na monko, e seng chefo, litšobotsi tse se nang mafome, tse se nang mafome, tse sebelisoang haholo indastering ea petrochemical bakeng sa Pompe ea Oli e Kentsoeng ka Metsing, pompo ea slurry, pompo ea metsi, Centrifugal Pump, joalo-joalo.

melemo

1, 100% lisebelisoa tse tala:

Lihlahla li hlahisoa ka lisebelisoa tse hloekileng tse tala, tse nang le litšobotsi tsa bophelo bo bolelele ba tšebeletso le ts'ebetso e tsitsitseng.

2, ho sebetsa:

Bushings e sebetsoa ka lisebelisoa tse nepahetseng haholo: Setsi sa machining sa CNC, mochini o silang, mochini o silang, mochini oa ho phunya, mochini o silang o otlolohileng, mochini oa chamfering, Metal Stamping, mochini o sehang oa CNC jj.

3, boholo bo bongata bo fumaneha:

Re ka fana ka li-bushings tse nang le boholo bo fapaneng, liforomo tse feletseng le nako e khutšoanyane ea ho fana. Matsatsi a 7-10 bakeng sa mehlala .20-25 matsatsi a ho sebetsa bakeng sa lihlahisoa tse ngata

4,Tiiso ea boleng:

Maemo a Boleng a ke keng a Feta

Hlahisa

Tlhaloso e qaqileng

Tafole ea lintho tse bonahalang

| Kereiti | ISO | Tlhaloso | Tšebeliso ea tungsten carbide | ||

| Botenya | TRS | Ho thatafala | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | E tšoaneleha bakeng sa machining ea chilled cast iron, alloy cast iron, refractory steel le alloy steel.E boetse e Tšoaneleha bakeng sa machining ea tšepe e tloaelehileng ea tšepe. |

| YG06 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | E tšoaneleha bakeng sa machining a ho qetela le a semi-finish bakeng sa tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, alloy le lisebelisoa tse sa kopanngoeng.E boetse e tšoaneleha bakeng sa ho taka terata bakeng sa tšepe le tšepe e seng ferrous, boro ea motlakase bakeng sa tšebeliso ea jeoloji le ho cheka tšepe joalo-joalo. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ea tšoanelehang bakeng sa machining a thata a tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, lisebelisoa tse se nang tšepe, ho taka tšepe, tšepe le liphaephe tse se nang ferrous, lisebelisoa tse fapaneng bakeng sa tšebeliso ea jeoloji, lisebelisoa tsa ho etsa mochine le likarolo tsa ho roala. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | E tšoaneleha bakeng sa machining a lebelo le tlase, alloy ea titanium le alloy refractory, haholo-holo bakeng sa lisebelisoa tse khaotsoeng le silika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ea tšoanelehang bakeng sa ho bopa libopo bakeng sa ho cheka lejoe le boima ba 'mele: likotoana tse senyehang tse sebelisetsoang ho cheka mekoti e tebileng, trolley ea rock jj. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | E tšoaneleha bakeng sa ho cheka lejoe le thata, litšepe tse nang le likhakanyo tse phahameng tsa compression, ho taka liphaephe, lisebelisoa tsa ho phunya, khabinete ea mantlha ea li-molder tsa powder metallurgy, joalo-joalo. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | E tšoaneleha bakeng sa ho etsa lifofu tse nang le tšusumetso e tlase joalo ka ho phunya likarolo tsa oache, likhetla tsa betri, li-screw caps tse nyane jj. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | E tšoaneleha bakeng sa ho etsa hlobo ea lihlooho tse batang, ho hatakela ka mokhoa o batang le ho hatella ho batang tse sebelisetsoang ho etsa likarolo tse tloaelehileng, li-bearings joalo-joalo. | |

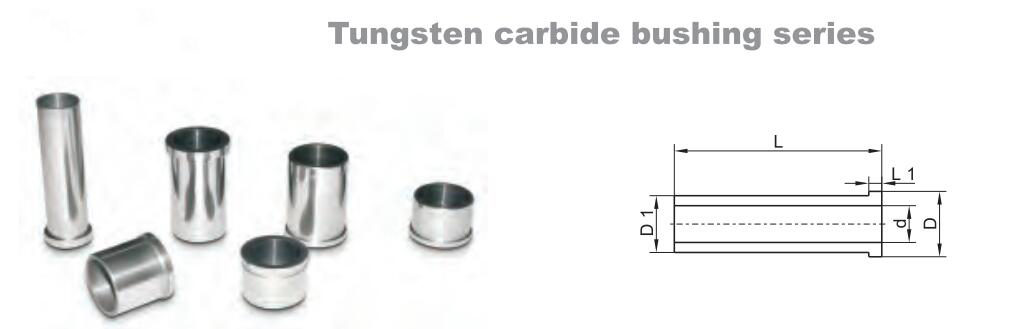

Tafole ea boholo

| Mohlala No. | Tlhaloso | OD(D:mm) | ID(D1:mm) | Pore(d:mm) | Bolelele(L:mm) | Bolelele ba mohato(L1:mm) |

| KD-2001 | 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| KD-2002 | 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| KD-2003 | 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| KD-2004 | 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| KD-2005 | 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| KD-2006 | 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| KD-2007 | 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| KD-2008 | 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| KD-2009 | 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| KD-2010 | 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |