Lihlahisoa

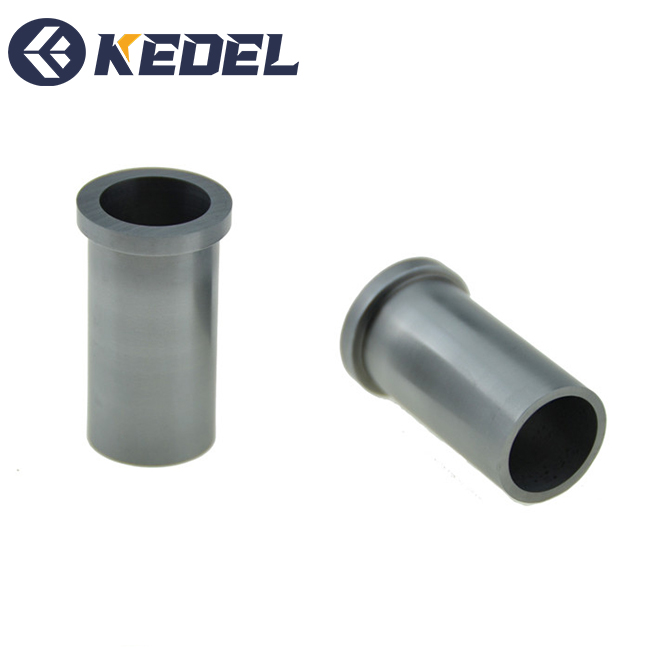

Anti Corrosion Tungsten Carbide Solid YG1C Threaded Drill Bushings

Kenyelletso ea Sehlahisoa

Tungsten carbide bushing e thehiloe ke virgin tungsten carbide material. E bontša boima bo phahameng le matla a ho koba. E na le ts'ebetso e phahameng ea ho hanela abrasion le corrosion, e sebelisoang haholo liindastering tse ngata.

Bakeng sa tšebeliso ea eona e pharaletseng. Tungsten carbide bushing hangata e entsoe ka nepo e phahameng, 'me ka lebaka la pheletso e phethahetseng, boholo bo nepahetseng, ho tšoarella le ho hanyetsa kutu. Tsena li ananeloa haholo ke bareki ba 'marakeng oa dostic le ka har'a sekepe.

Ho feta moo, e fapane le maemo a fapaneng a ts'ebeliso. Ho na le mefuta e 'maloa ea Tungsten carbide bushing. Bongata ba litlhaloso tsohle li hlophisitsoe. Kedel Tool e tšehelitsoe ke tsebo e ruileng ea indasteri le boiphihlelo ba tlhahiso ea mefuta e fapaneng ea Tungsten carbide bushing. Sena se ka hlahisa mefuta e fapaneng ea Tungsten carbide bushing e ipapisitseng le moralo o ikhethileng.

Likarolo tsa Sehlahisoa

1. Sebelisa 100% tungsten carbide thepa e tala

2. Lintho tse tsitsitseng tsa lik'hemik'hale

3. Ts'ebetso e ntle haholo le ts'ebetso e ntle ea ho roala / kutu

4. HIP sintering, molemo compactness

5. Likheo, ho nepahala ha machining / ho nepahala

6. OEM customized boholo bo fumaneha

7. Tlhahiso ea fektheri

8. Tlhahlobo e tiileng ea boleng ba lihlahisoa

Tlhaloso e qaqileng

Tafole ea lintho tse bonahalang

| Kereiti | ISO | Tlhaloso | Tšebeliso ea tungsten carbide | ||

| Botenya | TRS | Ho thatafala | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | E tšoaneleha bakeng sa machining ea chilled cast iron, alloy cast iron, refractory steel le alloy steel. E boetse e Tšoaneleha bakeng sa machining ea tšepe e tloaelehileng ea tšepe. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | E tšoaneleha bakeng sa machining a ho qetela le a semi-finish bakeng sa tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, alloy le lisebelisoa tse sa kopanngoeng. E boetse e tšoaneleha bakeng sa ho taka terata bakeng sa tšepe le tšepe e seng ferrous, boro ea motlakase bakeng sa tšebeliso ea jeoloji le ho cheka tšepe joalo-joalo. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ea tšoanelehang bakeng sa machining a thata a tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, lisebelisoa tse se nang tšepe, ho taka tšepe, tšepe le liphaephe tse se nang ferrous, lisebelisoa tse fapaneng bakeng sa tšebeliso ea jeoloji, lisebelisoa tsa ho etsa mochine le likarolo tsa ho roala. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | E tšoaneleha bakeng sa machining a lebelo le tlase, alloy ea titanium le alloy refractory, haholo-holo bakeng sa lisebelisoa tse khaotsoeng le silika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ea tšoanelehang bakeng sa ho bopa libopo bakeng sa ho cheka lejoe le boima ba 'mele: likotoana tse senyehang tse sebelisetsoang ho cheka mekoti e tebileng, trolley ea rock jj. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | E tšoaneleha bakeng sa ho cheka lejoe le thata, litšepe tse nang le likhakanyo tse phahameng tsa compression, ho taka liphaephe, lisebelisoa tsa ho phunya, khabinete ea mantlha ea li-molder tsa powder metallurgy, joalo-joalo. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | E tšoaneleha bakeng sa ho etsa lifofu tse nang le tšusumetso e tlase joalo ka ho phunya likarolo tsa oache, likhetla tsa betri, li-screw caps tse nyane jj. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | E tšoaneleha bakeng sa ho etsa hlobo ea lihlooho tse batang, ho hatakela ka mokhoa o batang le ho hatella ho batang tse sebelisetsoang ho etsa likarolo tse tloaelehileng, li-bearings joalo-joalo. | |