Lihlahisoa

Lithupa tsa Tungsten tse tiileng tsa Carbide

Carbide Rods Tlhaloso

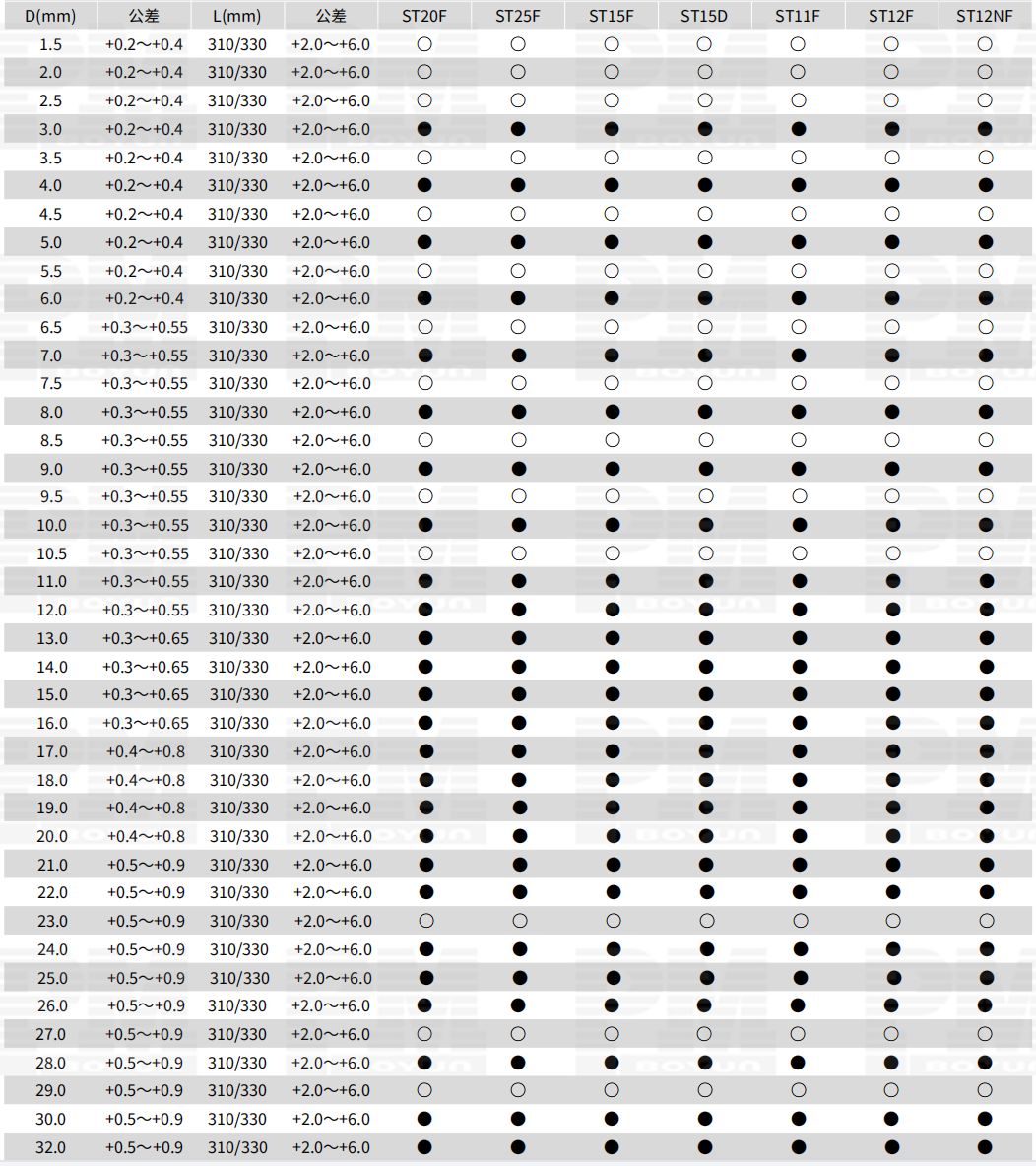

Li-tungsten carbide rods li sebelisoa haholo bakeng sa ho etsa lisebelisoa tsa premium solid carbide, tse kang li-mill, li-drill, reamers, li-milling cutters, li-stamping, le lisebelisoa tsa ho lekanya liindasteri tse sa tšoaneng. Khetho e felletseng ea lithupa tsa tungsten carbide ka litekanyo tse fapaneng lia fumaneha, hape re fana ka lits'ebeletso tsa ho iketsetsa ho latela litlhoko tsa hau. Joaloka moetsi oa ISO, Kedeltool e sebelisa lisebelisoa tsa boleng bo holimo ho netefatsa boleng le ts'ebetso ea lithupa tsa rona tsa carbide. Ka tlhahlobo e matla ea boleng, re ka netefatsa boleng bo tsitsitseng ka har'a sehlopha ka seng.

Mefuta ea Kedel Carbide Rod

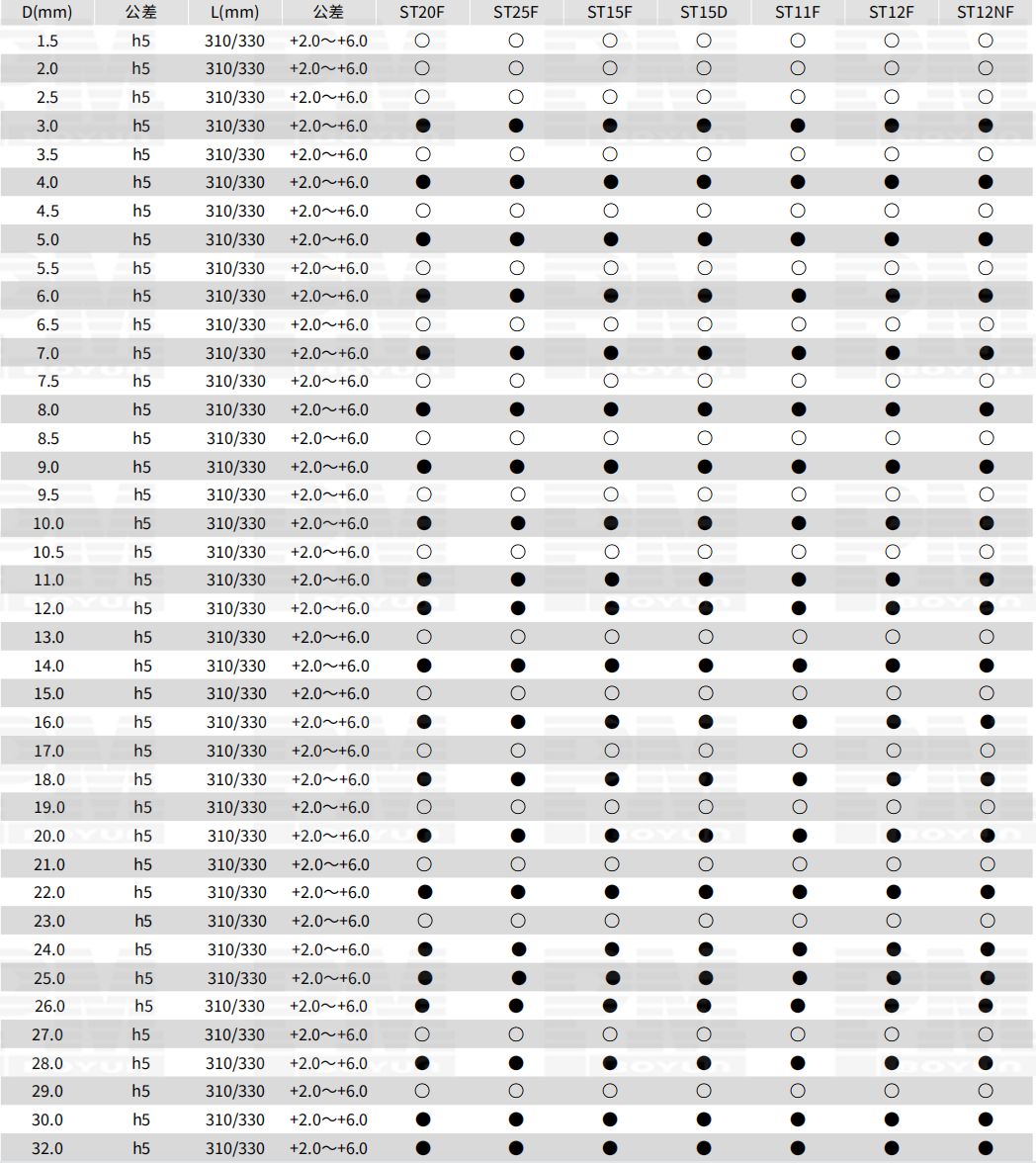

1. Melamu e tiileng ea Carbide ka Metrics

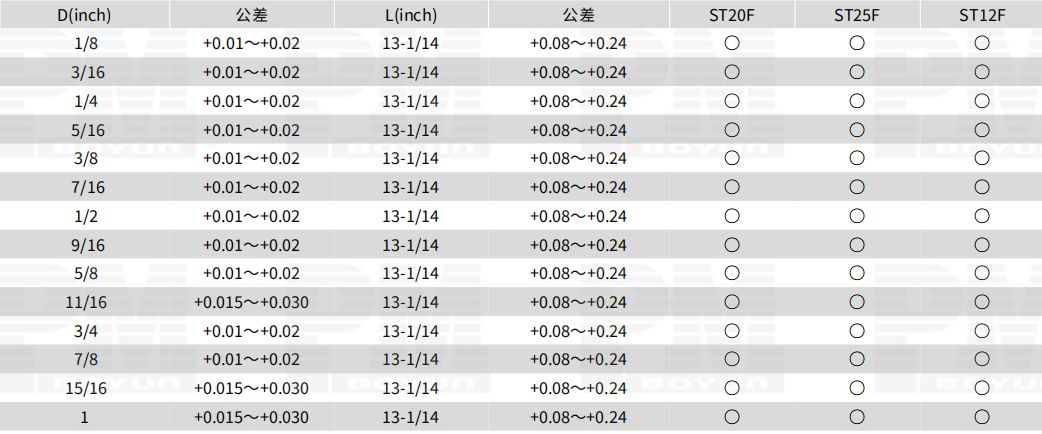

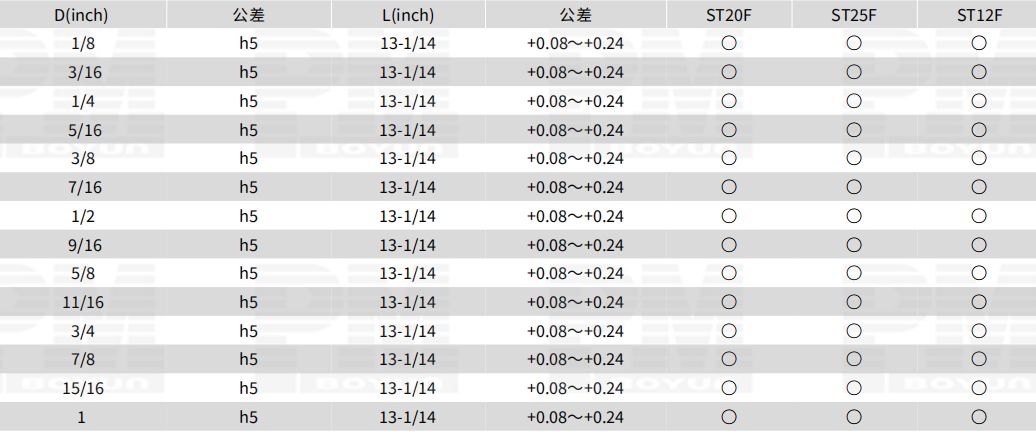

2. Lithupa tse tiileng tsa Carbide ka Inchi

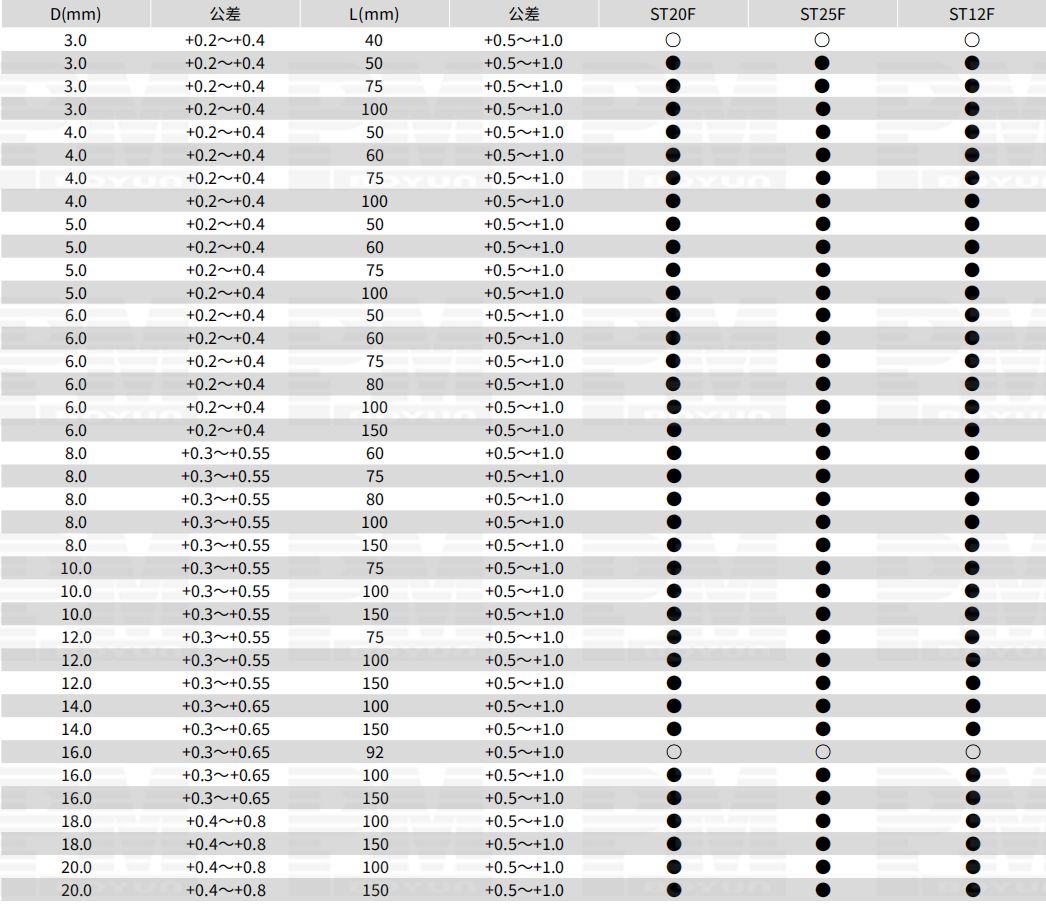

3. Drill Blanks (Chamfered)

4. End Mill Blanks (Chamfered)

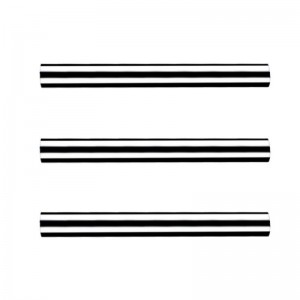

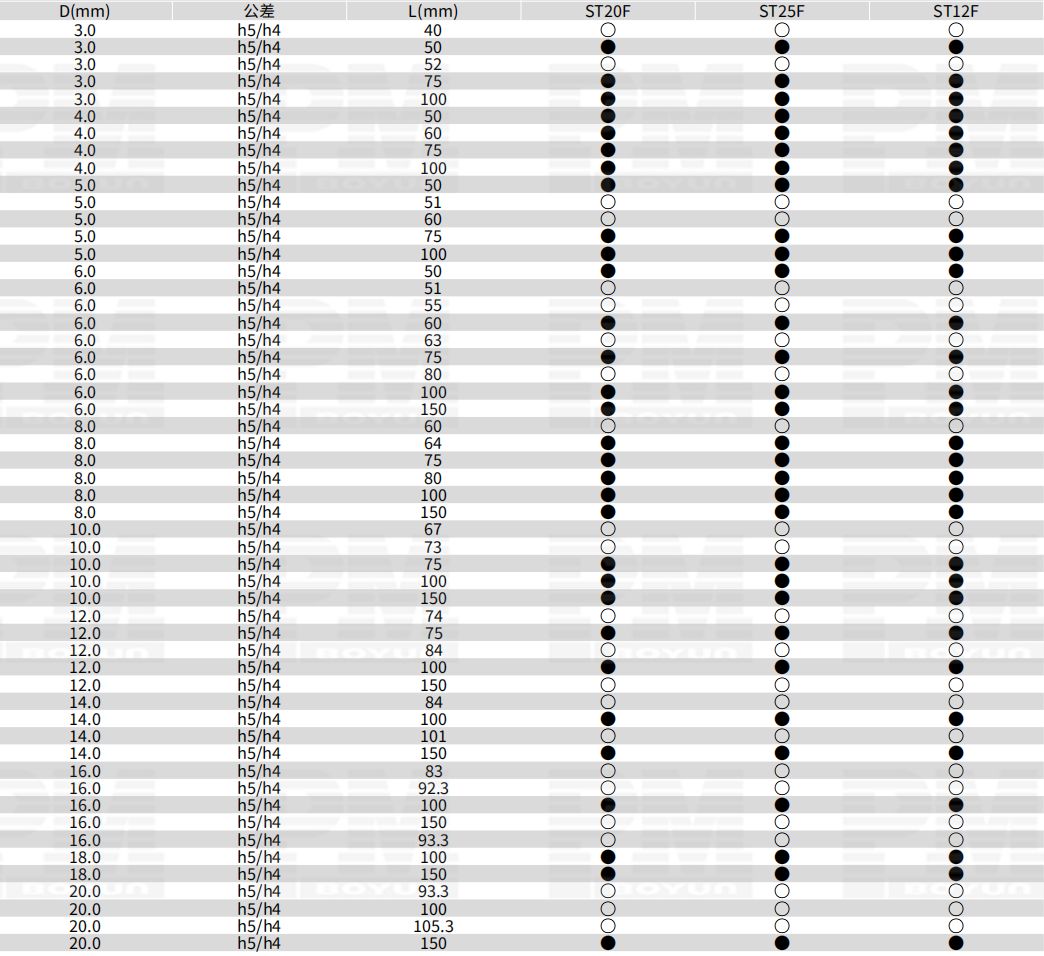

5. Lithupa tsa Carbide tse nang le Hole e Otlolohileng e Bohareng e Pholisang

6. Lithupa tsa Carbide tse nang le masoba a mabeli a otlolohileng a batang

Litšobotsi tsa Carbide Rod

1. E entsoe ka boleng bo phahameng ba tungsten carbide superfine phofo

2. Thepa e nepahetseng e nang le 10MPa HIP-Sinter setofo e entsoeng ka mokhoa o tloaelehileng.

3. Boima bo phahameng le matla a phahameng

4. Melemo e khethehileng: Bofubelu bo thata, ho apara ho hanyetsa, modulus e phahameng ea elasticity, TRS, botsitso ba lik'hemik'hale, ho hanyetsa tšusumetso, coefficient e tlaase ea dilatation, mocheso oa mocheso le motlakase oa motlakase o tšoanang le tšepe.

5. Theknoloji e khethehileng: sintering e phahameng ea khatello ea mocheso o phahameng oa mocheso. Fokotsa porosity, fokotsa compactness le thepa ea mechine. Mefuta e fapa-fapaneng, boholo le boholo.

6. Kereiti e fapaneng bakeng sa referense ea hau.

Mefuta e Tloaelehileng

Lenane la Kereiti

| Kenyelletso ea Kereiti ho Carbide Rods | |||||||

| Kereiti | Co % | WC boholo ba lijo-thollo | HRA | HV | Boima ba 'mele (g/cm³) | Matla a ho kobeha (MPa) | Bothata ba ho robeha (MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Hantle | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Bakeng sa tlhaiso-leseling e batsi (MOQ, theko, delibari) kapa haeba u hloka lits'ebeletso tsa ho ikamahanya le maemo, ka kopo kopa qotso.