Lihlahisoa

Feme e tobileng phepelo ea tungsten carbide thread nozzle YG8 YG10 YG15 bakeng sa PDC bit

Kenyelletso ea Tlhahiso

Nozzle e entsoeng ka samente ea carbide hangata e sebelisoa holim'a likotoana tsa ho cheka oli, tse ka hloekisang likotoana tsa ho cheka le bokatlase bo chekiloeng, 'me e tiile, e sa senyehe, ebile e na le bophelo bo bolelele ba ts'ebeletso. Carbide nozzle e tiile ebile e tšoarella, 'me e na le ts'ebetso ea theko e phahameng. Nozzle ea carbide e entsoeng ka samente e entsoe ka mechini e nepahetseng le lisebelisoa tse samente tsa carbide, tse nang le khanyetso ea 2300N / mm le boima ba likhato tse 90. Ha ho etsoa machining li-nozzles tsa carbide, re hloka ho fihlela ho sila ka nepo le kalafo ea holim'a metsi.

Likarolo tsa Sehlahisoa

1. 100% vergin lihlahisoa tse tala;

2. Limaraka le boholo bo fapaneng ba li-nozzle li fumaneha ho latela litlhoko tsa bareki;

3. Re na le lisebelisoa tsa ho sila tse nepahetseng tse tsoetseng pele le lisebelisoa tsa tlhahlobo ho netefatsa lihlahisoa tsa boleng bo holimo;

4. Lilemo tse fetang 10 tsa phihlelo ea tlhahiso, theknoloji e ruileng ea tlhahiso ea basebetsi ho etsa bonnete ba hore lihlahisoa li tsitsitse;

5. Boleng bo tsitsitseng ba sehlahisoa le tšebeletso e phethahetseng ka mor'a thekiso;

6. Sehlahisoa se na le matla a phahameng, khanyetso e phahameng ea abrasion le ho hanyetsa tšusumetso e matla;

Tafole ea tšebetso ea boemo ba lintho tse bonahalang

| Kereiti | Co(%) | Boima ba 'mele(g/cm3) | Ho thatafala(HRA) | TRS(NN/mm²) |

| YG6 | 5.5-6.5 | 14.90 | 90.50 | 2500 |

| YG8 | 7.5-8.5 | 14.75 | 90.00 | 3200 |

| YG9 | 8.5-9.5 | 14.60 | 89.00 | 3200 |

| YG9C | 8.5-9.5 | 14.60 | 88.00 | 3200 |

| YG10 | 9.5-10.5 | 14.50 | 88.50 | 3200 |

| YG11 | 10.5-11,5 | 14.35 | 89.00 | 3200 |

| YG11C | 10.5-11,5 | 14.35 | 87.50 | 3000 |

| YG13C | 12.7-13.4 | 14.20 | 87.00 | 3500 |

| YG15 | 14.7-15.3 | 14.10 | 87.50 | 3200 |

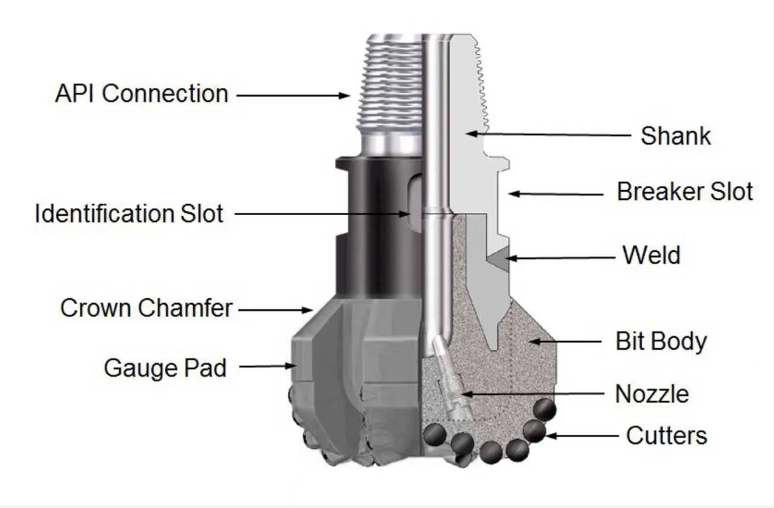

Setšoantšo sa lintlha tsa sehlahisoa

Sesebelisoa sa sehlahisoa