Lihlahisoa

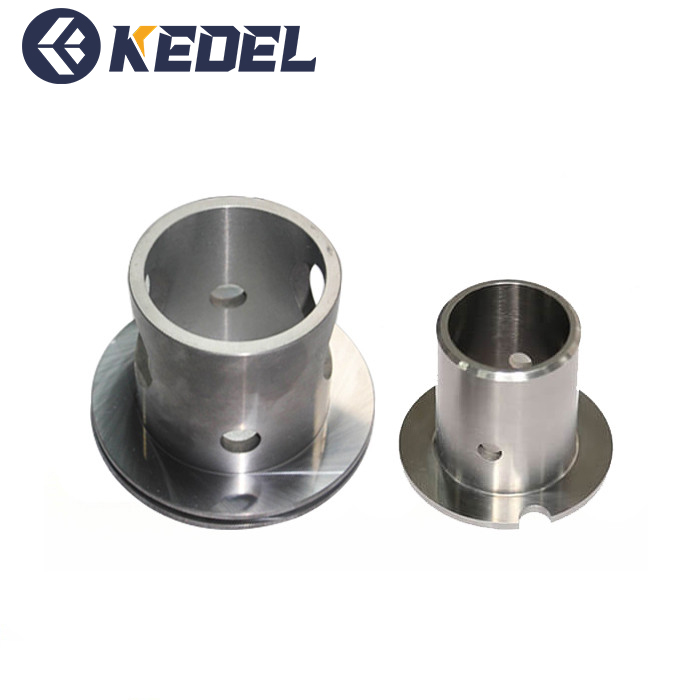

Customized Tungsten carbide Bushing Shaft Sleeve

Kenyelletso ea Sehlahisoa

Lisebelisoa tsa sehlahla sa Tungsten carbide li pharaletseng, e leng sesebelisoa sa ho sireletsa sehlopha sa likarolo. Ke mosebetsing oa sebele 'me karolo le morero oa tikoloho ea eona ea kopo li na le kamano e kholo. Lisebelisoa tsa li-valve, lihlahla li kenngoe ka har'a sefi sa valve stem cap, e le ho fokotsa ho lutla ha valve, ho tiisa; ho jara lits'ebetso, ts'ebeliso ea sehlahla ho fokotsa ho roala pakeng tsa ho beha le setulo sa shaft, qoba lekhalo lipakeng tsa shaft le ho eketseha ha lesoba joalo-joalo. Tungsten carbide sehlahla tlhahiso le ts'ebetso ea matla a phahameng, e ka mamella mojaro oa nako e telele, e nang le botsitso bo phahameng ba lik'hemik'hale, alkali, joala, ether, hydrocarbons, acid, oli, detergent, metsi (metsi a leoatle), 'me ha e na monko, litšobotsi tse se nang chefo, tse se nang mafome, tse se nang mafome, tse sebelisoang haholo indastering ea petrochemical bakeng sa pompo ea metsi e kentsoeng ka metsing, pompo ea metsi a metsi, pompo ea metsi.

Likarolo tsa Sehlahisoa

1. Tungsten Carbide Bearing Bushings e na le litlhaku tse phahameng tsa ho roala, ho hanyetsa kutu e phahameng le thepa e ntle ea khatello.

2. E sebelisoa haholo liindastering tsa petrochemical le liindasteri tse ling tse bitsang thepa e phahameng ea li-bearing bushings kapa matsoho a shaft.

3. Tungsten carbide HO HLAHALA ke thepa ea motheo har'a lisebelisoa tse ferekaneng. Li sebelisoa haholo e le likarolo tsa motheo tsa ho tiisa. 'Me lihlahla li amoheloa haholo indastering ea petrochemical ka lebaka la ts'ebetso ea eona e ntle joalo ka bokhoni ba ho apara, anti corrosion joalo-joalo.

Mokhoa oa Tlhahiso

Ho sila--Karohano kamoo ho hlokehang--Ho sila ka metsi--Omisa--Granulation--Press--Sinter--Inspection--Package

Lihlahisoa tse amanang

Lihlahla tsa Tungsten Carbide

Carbide Sleeves bakeng sa pompo ea centrifugal

Tataiso ea Tungsten Drill

Carbide Axle Shaft Sleeves

Li-plug tsa Carbide

Libolo tsa Carbide Valve.

Litulo le li-stems tsa Tungsten Carbide Valve

Oli ea Tungsten Carbide le Likarolo tsa Liaparo tsa Khase ea Tlhaho

Tungsten Carbide Nozzles

Likarolo tsa Pump ea Khatello e Phahameng ea Tungsten Carbide

Tungsten Carbide bakeng sa -Flow Restrictors

Likarolo tsa Pompo ea Centrifugal

Centrifugal Carbide Apara Lithaele

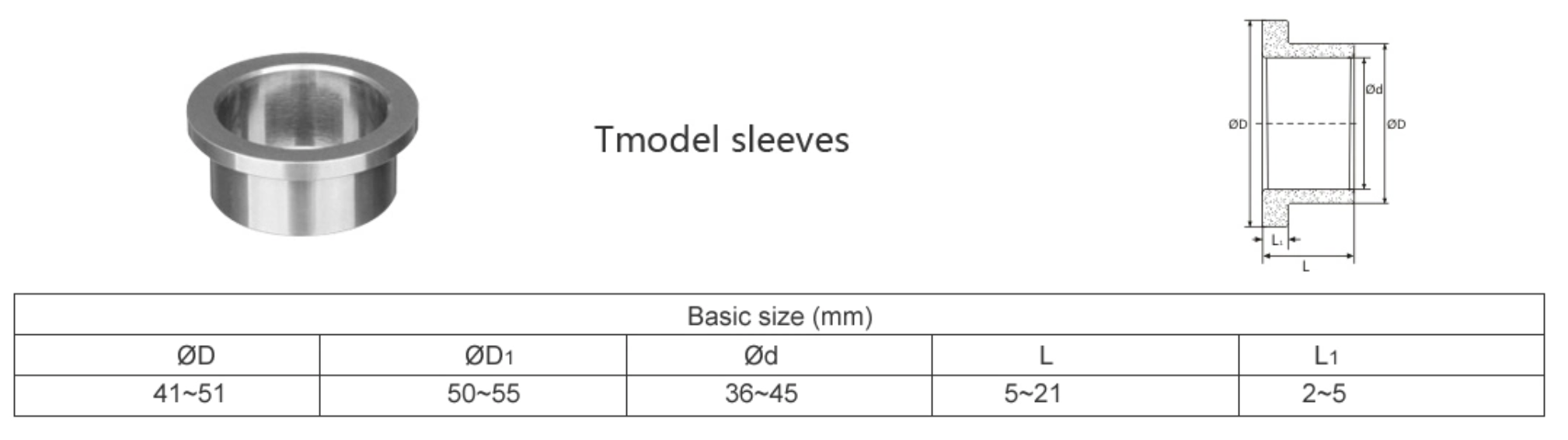

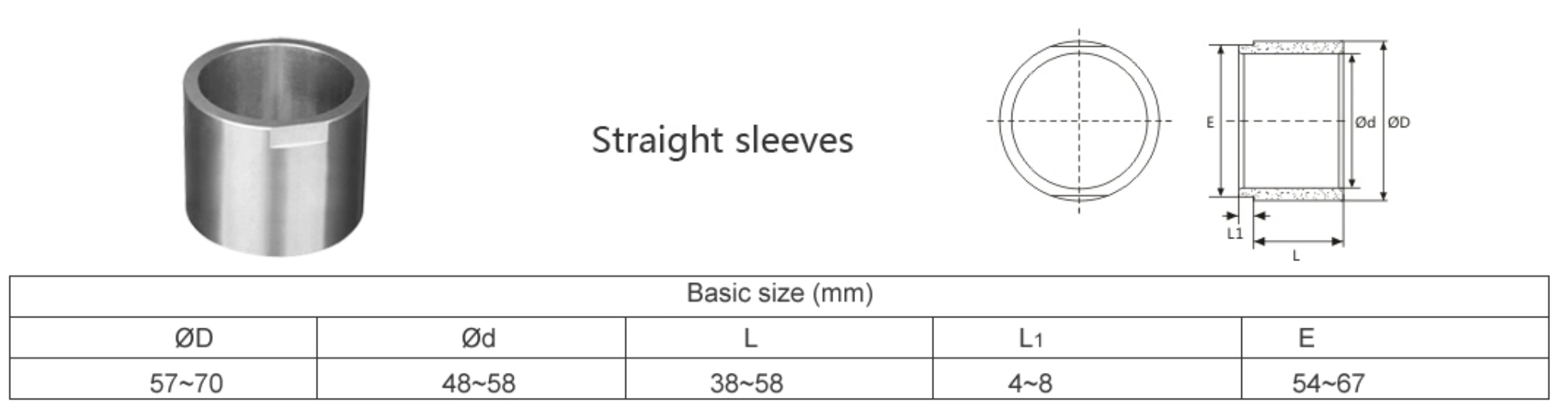

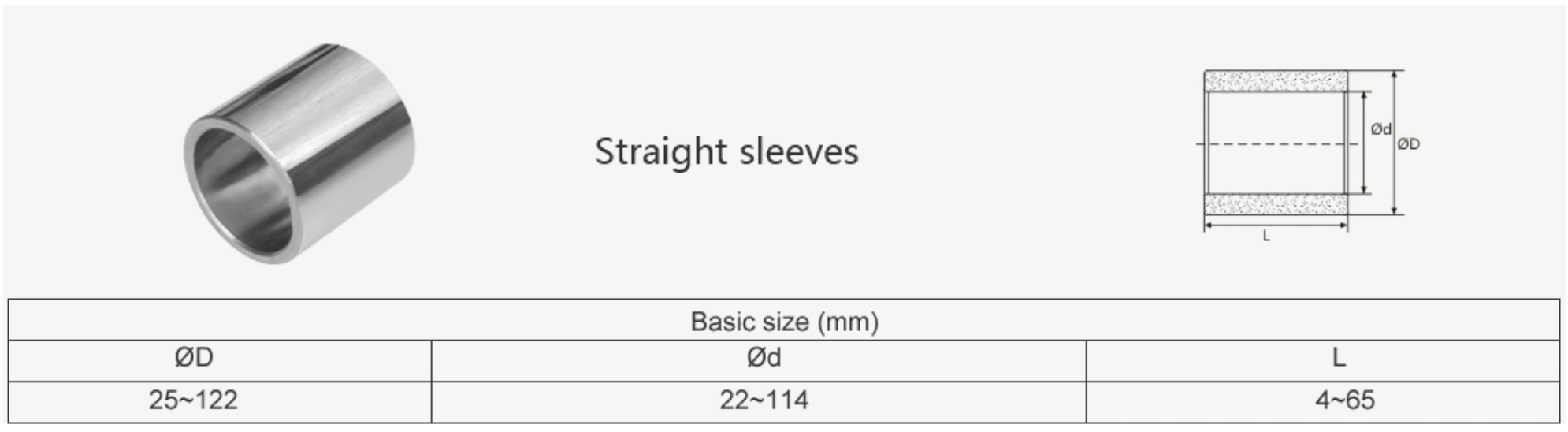

Setšoantšo sa boholo ba sehlahisoa

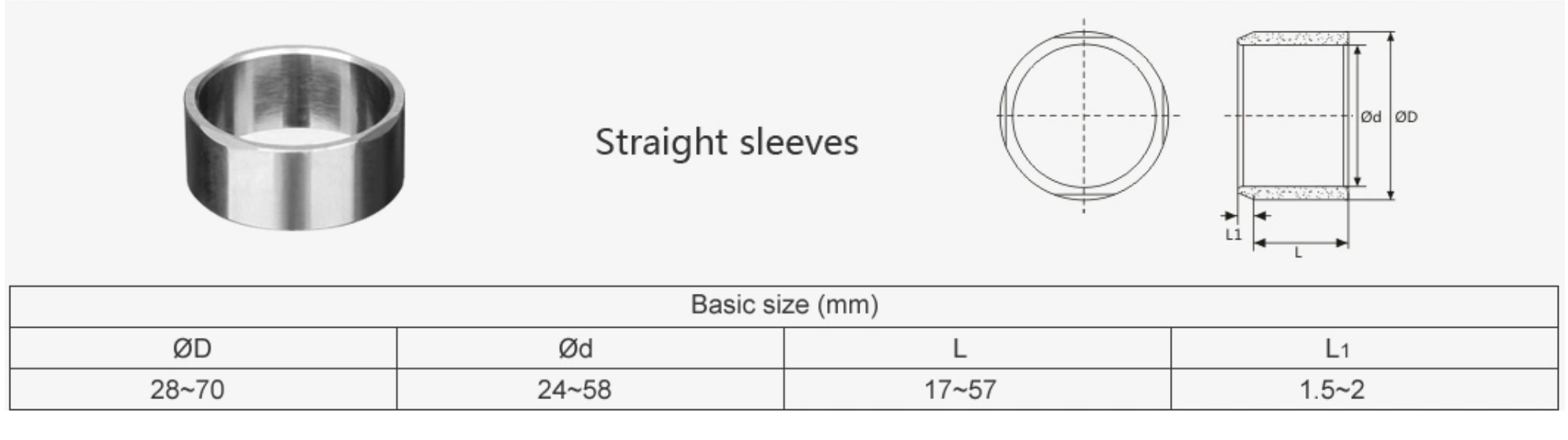

Tafole ea lintho tse bonahalang

| Kereiti | ISO | Tlhaloso | Tšebeliso ea tungsten carbide | ||

| Botenya | TRS | Ho thatafala | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | E tšoaneleha bakeng sa machining ea chilled cast iron, alloy cast iron, refractory steel le alloy steel. E boetse e Tšoaneleha bakeng sa machining ea tšepe e tloaelehileng ea tšepe. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | E tšoaneleha bakeng sa machining a ho qetela le a semi-finish bakeng sa tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, alloy le lisebelisoa tse sa kopanngoeng. E boetse e tšoaneleha bakeng sa ho taka terata bakeng sa tšepe le tšepe e seng ferrous, boro ea motlakase bakeng sa tšebeliso ea jeoloji le ho cheka tšepe joalo-joalo. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ea tšoanelehang bakeng sa machining a thata a tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, lisebelisoa tse se nang tšepe, ho taka tšepe, tšepe le liphaephe tse se nang ferrous, lisebelisoa tse fapaneng bakeng sa tšebeliso ea jeoloji, lisebelisoa tsa ho etsa mochine le likarolo tsa ho roala. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | E tšoaneleha bakeng sa machining a lebelo le tlase, alloy ea titanium le alloy refractory, haholo-holo bakeng sa lisebelisoa tse khaotsoeng le silika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ea tšoanelehang bakeng sa ho bopa libopo bakeng sa ho cheka lejoe le boima ba 'mele: likotoana tse senyehang tse sebelisetsoang ho cheka mekoti e tebileng, trolley ea rock jj. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | E tšoaneleha bakeng sa ho cheka lejoe le thata, litšepe tse nang le likhakanyo tse phahameng tsa compression, ho taka liphaephe, lisebelisoa tsa ho phunya, khabinete ea mantlha ea li-molder tsa powder metallurgy, joalo-joalo. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | E tšoaneleha bakeng sa ho etsa lifofu tse nang le tšusumetso e tlase joalo ka ho phunya likarolo tsa oache, likhetla tsa betri, li-screw caps tse nyane jj. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | E tšoaneleha bakeng sa ho etsa hlobo ea lihlooho tse batang, ho hatakela ka mokhoa o batang le ho hatella ho batang tse sebelisetsoang ho etsa likarolo tse tloaelehileng, li-bearings joalo-joalo. | |