Lihlahisoa

Ho hanyetsa Corrosion Resistance e bentšitsoeng ea Tungsten Carbide Bushing Sleeve

Kenyelletso ea Sehlahisoa

Mokotla o entsoeng ka samente oa carbide axle o tla sebelisoa haholo bakeng sa tšehetso e potolohang, ho hokahanya anti-thrust le tiiso ea axle ea moter, centrifuge, mosireletsi le karohano ea pompo ea motlakase e kentsoeng ka metsing maemong a mabe a ho potoloha ka lebelo le phahameng, lehlabathe la lash abrasion le kutu ea khase ka har'a mochini oa oli, joalo ka ho tsamaisa oli, sleeve, anti-thrust bearing sleeve le seal axle sleeve.

Melemo

1. 100% lihlahisoa tse tala.

2. Mefuta e fapaneng ea limaraka e fumaneha ho latela kopo ea moreki.

3. re na le mohala o tsoetseng pele oa tlhahiso le lisebelisoa tsa inspection ho netefatsa lihlahisoa tsa boleng bo holimo.

4. Precision Ground le mokhoa o phahameng oa polishing

5. Ho hanyetsa ho apara ho phahameng, boima bo phahameng le ho ba le tšusumetso e matla

6. Theknoloji e tsoetseng pele , ho sila ho nepahetseng.

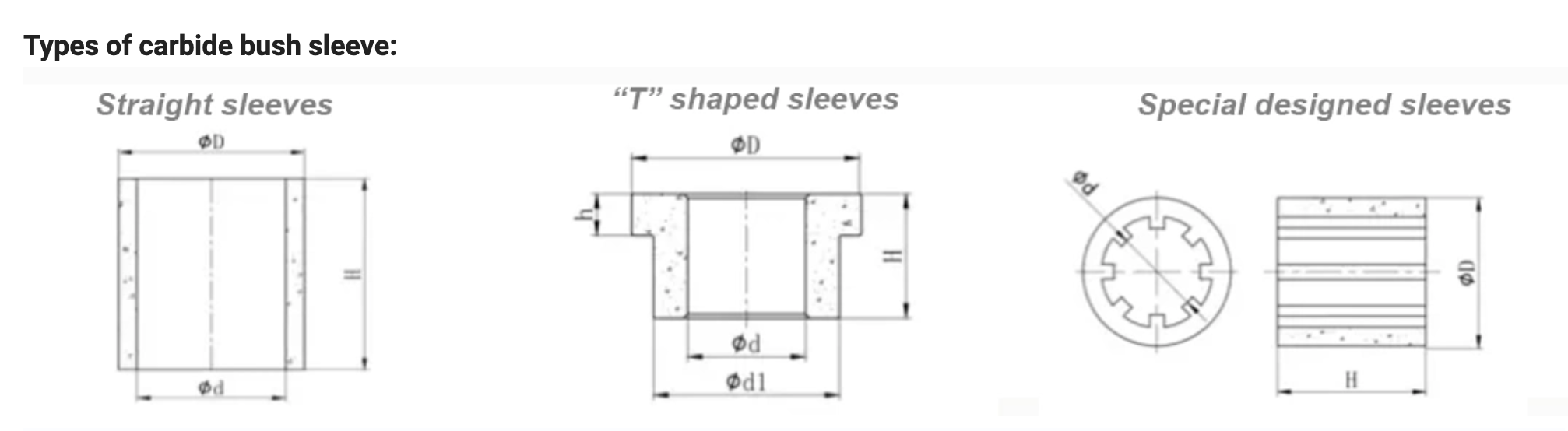

Mofuta oa casing

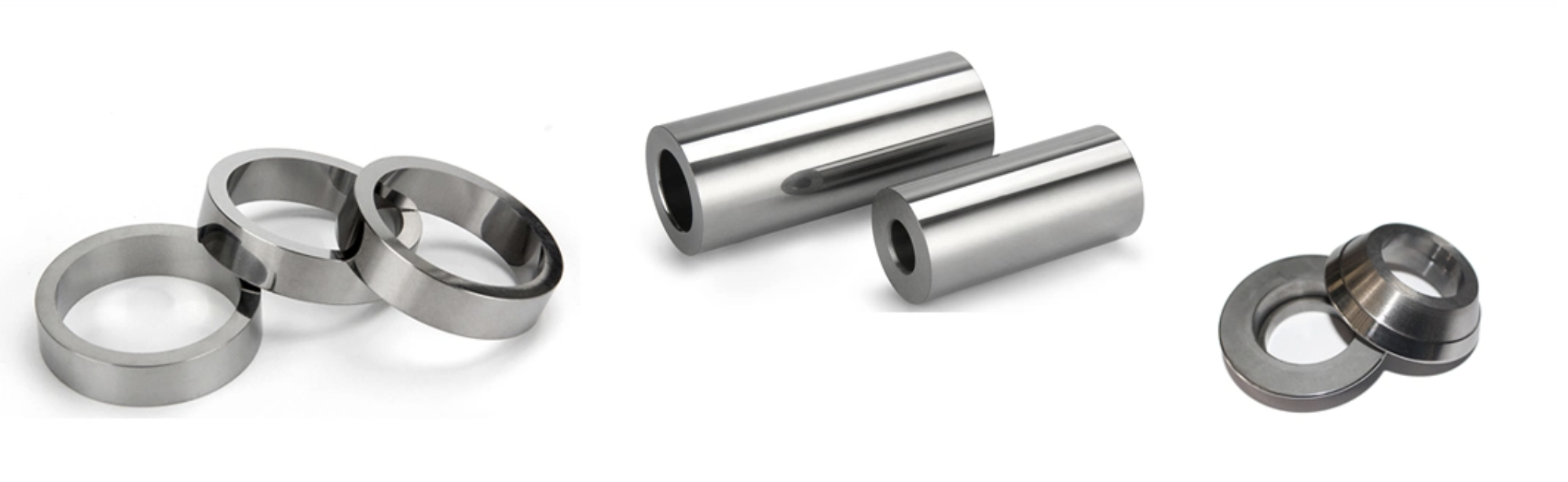

Setšoantšo sa casing

Tafole ea lintho tse bonahalang

| Kereiti | ISO | Tlhaloso | Tšebeliso ea tungsten carbide | ||

| Botenya | TRS | Ho thatafala | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | E tšoaneleha bakeng sa machining ea chilled cast iron, alloy cast iron, refractory steel le alloy steel. E boetse e Tšoaneleha bakeng sa machining ea tšepe e tloaelehileng ea tšepe. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | E tšoaneleha bakeng sa machining a ho qetela le a semi-finish bakeng sa tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, alloy le lisebelisoa tse sa kopanngoeng. E boetse e tšoaneleha bakeng sa ho taka terata bakeng sa tšepe le tšepe e seng ferrous, boro ea motlakase bakeng sa tšebeliso ea jeoloji le ho cheka tšepe joalo-joalo. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ea tšoanelehang bakeng sa machining a thata a tšepe e entsoeng ka tšepe, tšepe e se nang ferrous, lisebelisoa tse se nang tšepe, ho taka tšepe, tšepe le liphaephe tse se nang ferrous, lisebelisoa tse fapaneng bakeng sa tšebeliso ea jeoloji, lisebelisoa tsa ho etsa mochine le likarolo tsa ho roala. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | E tšoaneleha bakeng sa machining a lebelo le tlase, alloy ea titanium le alloy refractory, haholo-holo bakeng sa lisebelisoa tse khaotsoeng le silika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ea tšoanelehang bakeng sa ho bopa libopo bakeng sa ho cheka lejoe le boima ba 'mele: likotoana tse senyehang tse sebelisetsoang ho cheka mekoti e tebileng, trolley ea rock jj. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | E tšoaneleha bakeng sa ho cheka lejoe le thata, litšepe tse nang le likhakanyo tse phahameng tsa compression, ho taka liphaephe, lisebelisoa tsa ho phunya, khabinete ea mantlha ea li-molder tsa powder metallurgy, joalo-joalo. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | E tšoaneleha bakeng sa ho etsa lifofu tse nang le tšusumetso e tlase joalo ka ho phunya likarolo tsa oache, likhetla tsa betri, li-screw caps tse nyane jj. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | E tšoaneleha bakeng sa ho etsa hlobo ea lihlooho tse batang, ho hatakela ka mokhoa o batang le ho hatella ho batang tse sebelisetsoang ho etsa likarolo tse tloaelehileng, li-bearings joalo-joalo. | |