Lihlahisoa

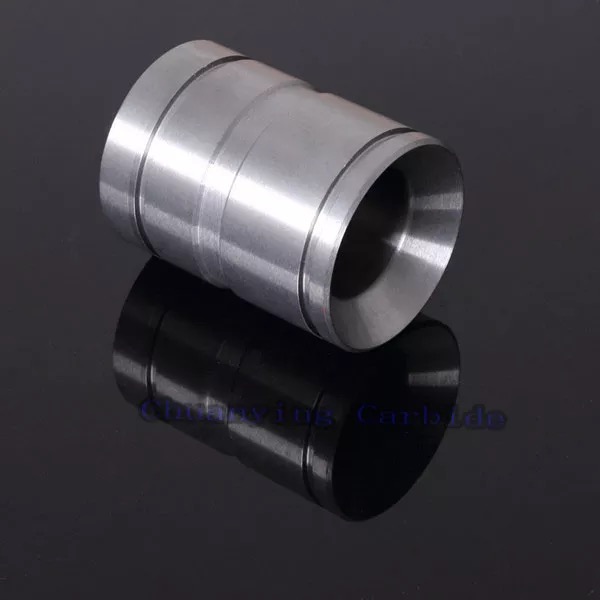

Tungsten Carbide Bushing Shaft Sleeve Bushing Bearing

Tlhaloso ea Lihlahisoa

Li-bushigns tse entsoeng ka samente ea carbide ke sehlahisoa se ikhethileng sa k'hamphani ea rona bakeng sa bareki. E na le thepa ea ho hanyetsa ho apara holimo, boima bo phahameng le khanyetso e matla ea kutu. E ka hlahisa li-liner tsa boholo bo fapaneng 'me ea fa bareki monyetla o ikhethang oa tlhahiso le tlhahiso ea tlhahiso.

Kedel Carbide Components e etsa Tungsten Carbide ea boleng bo holimo, Ceramic le Tool Wear Parts, MWD Components le Specialty Components bakeng sa lisebelisoa tse senyang le tse senyang bakeng sa indasteri ea oli le khase ea tlhaho.

Re etsa likarolo tse ngata tse kang likarolo tsa taolo ea phallo, lihlahla, litulo, liheke le lithupa ho likotoana tsa ho itšeha ka carbide, li-ported flow cages le li-thrust bearings.

Lik'hamphani tse ngata tsa Oli le Khase li itšetlehile ka Kedel Carbide Components ho etsa likarolo tsa taolo ea phallo ea tungsten carbide ea nako e telele. Botumo ba rona ba ho etsa likarolo tsa boleng ba ho roala le likarolo tsa taolo ea phallo bo bakoa ke boiphihlelo ba rona indastering, limaraka tse tsoetseng pele tsa tungsten carbide le boitlamo ho bareki ba rona.

Likarolo Tsa Rōna

1. Tsepamisa maikutlo tlhahisong ea indasteri ea carbide e samente ka lilemo tse fetang 15;

2. Metsoako ea mefuta e fapaneng e felile, e ka fihlelang litlhoko tsa ts'ebetso ea ho hloleha;

3. Matla a matla a ho sebetsa, lisebelisoa tse fetang 50 tsa mochine oa CNC, li-grinders tse fetang 20 le li-grinders tse fetang 20 tsa bokahohle;

4. Tlhahiso e hlophisitsoeng bakeng sa bareki, OEM le ODM;

5. Phihlelo e ruileng ea litšebeletso tsa bareki ba kantle ho naha, e sebeletsa bareki linaheng tse fetang 50 lefatšeng ka bophara.

More Tungsten Carbide Bushings Bearing Bush

Lethathamo la Ts'ebetso ea Material

| Lihlopha tsa Cobalt Binder | ||||

| Kereiti | Binder (Wt%) | Boima ba 'mele (g/cm3) | Ho thatafala (HRA) | TRS (>=N/mm²) |

| YG6 | 6 | 14.8 | 90 | 1520 |

| YG6X | 6 | 14.9 | 91 | 1450 |

| YG6A | 6 | 14.9 | 92 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88 | 1810 |

| YG15 | 15 | 14 | 87 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84 | 2550 |

| Nickel Binder Kereiti | ||||

| Kereiti | Binder (Wt%) | Boima ba 'mele (g/cm3) | Ho thatafala (HRA) | TRS (>=N/mm²) |

| YN6 | 6 | 14.7 | 89.5 | 1460 |

| YN6X | 6 | 14.8 | 90.5 | 1400 |

| YN6A | 6 | 14.8 | 91 | 1480 |

| YN8 | 8 | 14.6 | 88.5 | 1710 |